What Are Sublimation Leatherette Patches and How Are They Made?

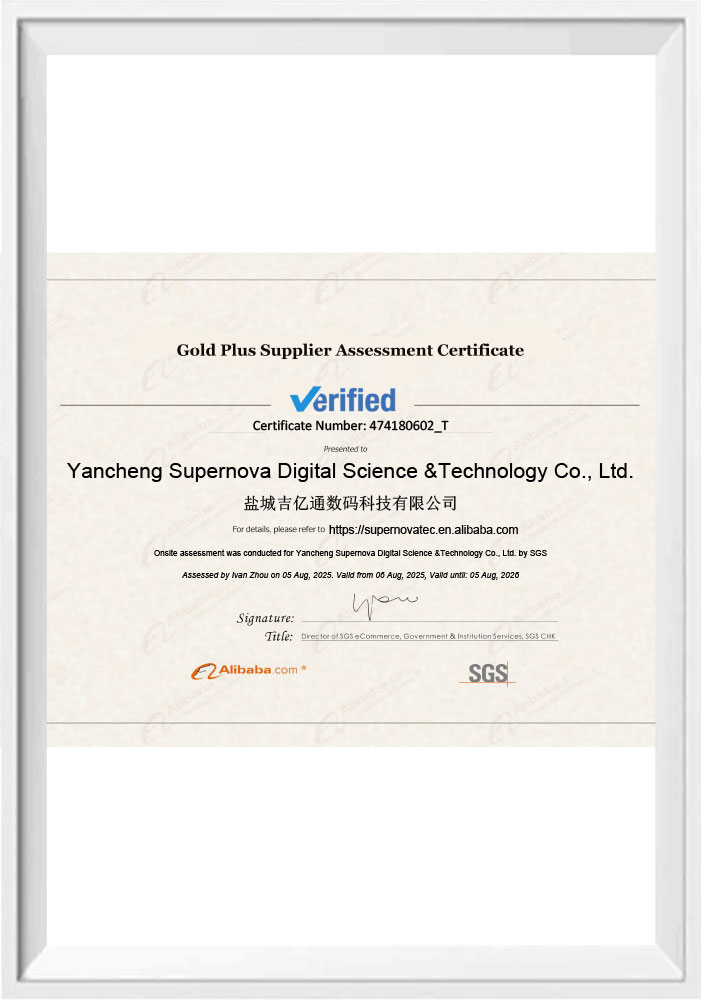

Sublimation Leatherette Patches have become an increasingly popular material in the personalized custom products market. These patches are favored for their durability, realistic appearance, and ability to produce high-quality sublimation prints. They are widely used in products such as fashion accessories, office supplies, gifts, and creative merchandise. As one of the core products of Yancheng Supernova Digital Science & Technology Co., Ltd., our sublimation leatherette patches combine advanced manufacturing techniques with fine raw materials to meet the growing demand for personalized, environmentally friendly, and durable products.

What Are the Key Components of Sublimation Leatherette Patches?

The core component of sublimation leatherette patches is high-quality synthetic leather material, commonly known as leatherette. This material is typically made from polyurethane (PU) or polyvinyl chloride (PVC) combined with other synthetic fibers. Compared to traditional leather, sublimation leatherette patches are more environmentally friendly as they do not rely on animal products, while still offering the same appearance and texture as genuine leather.

- Polyurethane (PU): PU is one of the main components in sublimation leatherette patches. It provides excellent flexibility, abrasion resistance, and aging resistance. PU materials offer the realistic look and feel of leather while keeping the weight of the product lighter, making it more convenient and comfortable for everyday use.

- Polyvinyl Chloride (PVC): PVC is a cost-effective synthetic material often used for producing leather substitutes. It offers excellent water resistance and stain resistance, making it ideal for everyday items and accessories.

- Coating Layer: To enable sublimation printing, the surface of the leatherette material is coated with a special polyester coating. This coating ensures the material has excellent ink absorption properties, which is critical for achieving high-quality and vibrant sublimation prints.

How Are Sublimation Leatherette Patches Made?

The production process of sublimation leatherette patches involves several meticulous steps to ensure the final product has excellent quality and precise graphic reproduction. Yancheng Supernova Digital Science & Technology Co., Ltd. is committed to technological innovation. We guarantee that each batch of sublimation leatherette patches meets industry standards by using advanced production equipment and a stringent quality management system.

- Raw Material Preparation: We begin by sourcing high-quality polyurethane (PU) and polyvinyl chloride (PVC) materials from leading global suppliers. All raw materials undergo rigorous screening and quality testing to ensure they are free from harmful substances and meet environmental standards. These materials are customized according to different requirements, such as coating thickness and type.

- Surface Coating Process: Next, we apply a uniform layer of polyester coating to the surface of the synthetic leather. The thickness and uniformity of this coating are crucial to the sublimation printing effect. Yancheng Supernova uses advanced equipment to ensure that the coating adheres well to different materials and that the printing effect is optimized.

- Sublimation Printing: This is the key process in producing sublimation leatherette patches. During this step, we use a sublimation printer to transfer custom designs onto the leatherette surface. The printer heats the ink to a high temperature, causing it to vaporize and permeate the polyester coating on the leatherette, resulting in vibrant colors and sharp patterns. Compared to traditional printing methods, sublimation printing offers better color fidelity and greater durability.

- Cutting and Finishing: After sublimation printing, the patches move to the cutting stage. We use laser cutting technology to precisely cut large sheets of leatherette into various shapes and sizes. This cutting method is efficient and highly accurate, allowing for customization based on customer needs. Additionally, the cut patches undergo finishing processes to ensure smooth edges and symmetrical shapes.

- Quality Inspection and Packaging: Finally, each sublimation leatherette patch undergoes strict quality inspection to ensure there are no defects or color discrepancies. Yancheng Supernova pays attention to detail, and all products are checked manually and through automated equipment to ensure consistent product quality. Once the patches pass inspection, they are carefully packaged to prevent any damage during transportation.

What Are the Advantages of Sublimation Leatherette Patches?

- High-Quality Graphic Reproduction: Due to the sublimation printing process, sublimation leatherette patches are capable of producing intricate and vibrant designs. This printing method ensures that the colors last longer and are more resistant to fading compared to traditional printing methods.

- Eco-Friendly and Sustainable: Unlike natural leather, sublimation leatherette patches are made from synthetic materials that do not rely on animal products, making them more environmentally friendly. Our products comply with global environmental regulations and offer consumers a greener, more sustainable option.

- Durability: Sublimation leatherette patches not only look realistic but also offer excellent durability. Even with regular use, the product maintains its aesthetic and functional integrity, making it suitable for long-term use.

- Wide Customization Possibilities: We offer sublimation leatherette patches in various sizes, colors, and shapes, and we support customers' specific design needs. Whether for corporate gifts, personalized accessories, or everyday items, sublimation leatherette patches can showcase unique styles and branding.

Why Are Sublimation Leatherette Patches More Suitable for Custom Products than Traditional Leather?

As the personalized customization market continues to grow, consumer demand for custom products has increased significantly. Whether in fashion accessories, office supplies, creative gifts, or promotional items, customized elements have become an important factor in attracting customers. As a company specializing in sublimation and laser engraving technologies, Yancheng Supernova Digital Science & Technology Co., Ltd. provides sublimation leatherette patches that offer superior advantages over traditional leather for custom products. This article will explain in detail why sublimation leatherette patches are more suitable for customized products than traditional leather from multiple perspectives.

1. Superior Printing Effects and Color Performance

Traditional leather often struggles to present fine printing effects due to its natural texture and ink absorption properties. Sublimation leatherette patches, on the other hand, use synthetic leather as the base material, and their surface undergoes a special coating treatment that enables excellent sublimation printing performance. The sublimation printing process allows designs to penetrate deep into the material rather than just sitting on the surface, ensuring vibrant, long-lasting colors that are less prone to fading.

For customized products, this means that whether it’s a single-color design or a complex multi-color pattern, sublimation leatherette patches can present extremely clear and durable graphics. In contrast, traditional leather printing methods often have limitations and may not achieve the same level of precision, especially when dealing with intricate or detailed designs.

2. Environmental Friendliness and Sustainability

With the growing awareness of environmental issues, more and more consumers and businesses are prioritizing the sustainability of their products. Traditional leather typically comes from animal hides, which not only involves animal slaughter in the production process but also uses a large amount of chemicals that can cause environmental pollution. In contrast, sublimation leatherette patches are made from synthetic materials (such as polyurethane, PVC, etc.) and do not rely on any animal-based raw materials, making them more environmentally friendly.

Yancheng Supernova Digital Science & Technology Co., Ltd. is committed to using eco-friendly synthetic materials to produce sublimation leatherette patches. All of our products meet global environmental standards, ensuring that our consumers receive safe and green customized products. Our sublimation leatherette patches are non-toxic and comply with environmental regulations in Europe and the United States.

3. Greater Durability and Adaptability

While traditional leather does have its advantages in terms of durability, it is less resistant to moisture, stains, and exposure to sunlight. Over time, traditional leather can fade, deform, or degrade when exposed to high humidity or direct sunlight. In contrast, sublimation leatherette patches, made from synthetic materials, offer better water resistance and weather resistance, allowing them to maintain their appearance and functionality over time. Even when used in humid or high-temperature environments, sublimation leatherette patches can retain their original designs and colors, far outperforming traditional leather.

Moreover, sublimation leatherette patches have a smoother surface, making them easier to clean and maintain. They are less likely to retain stains or scratches, making them a more convenient and durable choice for custom products.

4. Higher Production Efficiency and Cost-Effectiveness

The production process for traditional leather products is relatively complex, requiring several steps such as cutting, dyeing, and embossing, with each step potentially impacting the final product’s quality. In contrast, the production of sublimation leatherette patches is more streamlined, especially in the printing process, where sublimation technology allows direct and efficient pattern transfer onto the leatherette surface, eliminating many of the steps required by traditional methods.

Yancheng Supernova Digital Science & Technology Co., Ltd. utilizes advanced production technologies to reduce the production cost of sublimation leatherette patches while shortening production cycles. This not only ensures high product quality but also provides customers with more competitive pricing.

5. More Customization Options

Sublimation leatherette patches offer more customization options than traditional leather. They can be tailored in terms of size, color, shape, and surface treatment to meet specific customer needs. This versatility provides greater creative freedom and allows for more personalized designs.

For example, Yancheng Supernova Digital Science & Technology Co., Ltd. offers various texture and color options for our sublimation leatherette patches, allowing customers to customize the appearance of the patches to suit their specific product needs. Whether for gift customization, corporate giveaways, or personal accessories, sublimation leatherette patches can provide a unique style for each product.

6. Versatility in Application

Sublimation leatherette patches not only mimic the appearance of traditional leather but also have broader applicability. Whether used as part of a gift set, keychain, coaster, or as high-end stationery covers, notebook covers, and diary covers, sublimation leatherette patches can match a variety of products and offer diverse design options.

Yancheng Supernova Digital Science & Technology Co., Ltd. continuously explores new application scenarios and industry demands in the development of sublimation leatherette patches. Our products are widely used in multiple industries, especially in the high-end custom product market, where they have received high praise from consumers and corporate clients.

7. More Precise Production and Quality Control

By introducing advanced laser engraving technology and sublimation printing equipment, Yancheng Supernova Digital Science & Technology Co., Ltd. can achieve high-precision customization, ensuring that each sublimation leatherette patch’s pattern and cut are flawless. Traditional leather processing often relies on manual labor, which can introduce errors and inconsistencies. In contrast, modern production equipment allows our sublimation leatherette patches to meet higher quality standards and ensures consistency across batches.

Which Surfaces or Materials Are Not Suitable for Sublimation Leatherette Patches?

With the continuous growth of the personalized customization market, Sublimation Leatherette Patches have become a widely used material, especially for custom products like accessories, office supplies, gifts, and more. However, while sublimation leatherette patches offer many advantages and are applied in multiple industries, not all surfaces and materials are suitable for sublimation printing. Selecting the appropriate surface and material is crucial to ensure the quality, durability, and customer satisfaction of the printed product.

As a company specializing in sublimation and laser technologies, Yancheng Supernova Digital Science & Technology Co., Ltd. has been committed to the research and development of sublimation materials for many years. Our sublimation leatherette patches, combined with advanced manufacturing processes, ensure premium quality and precision in every product. However, we have identified certain surfaces and materials that are not suitable for sublimation printing. Below are the main materials and surface types that are not ideal for sublimation leatherette patches.

1. Are Materials with Oily, Waxy, or Water-Based Coatings Suitable for Sublimation?

The sublimation printing process relies on heat to vaporize the ink and transfer it into the surface. If a material has an oily, waxy, or water-based coating, this will affect the ink’s ability to penetrate the surface, resulting in poor printing quality. Oily or waxy coatings not only reduce the ink’s adhesion but may also cause the design to fade or blur over time.

For example, certain plastic surfaces may have a waterproof coating, which can block sublimation ink from penetrating the surface, leading to unclear or distorted images. To achieve optimal sublimation results, it is best to choose materials without coatings or those specifically designed for sublimation printing.

2. Are Excessively Smooth Surfaces Suitable for Sublimation Printing?

Excessively smooth surfaces can negatively impact the adhesion of sublimation ink. Sublimation printing requires a certain level of surface texture to ensure that the ink is able to bond properly with the material. If the material’s surface is too smooth, the ink will not penetrate evenly, leading to poor color intensity, blurry edges, or uneven color distribution.

Materials such as glossy metals or glass have very smooth surfaces. While these materials can be engraved with lasers, they are not suitable for sublimation printing. Yancheng Supernova Digital Science & Technology Co., Ltd.’s sublimation leatherette patches are designed to work best on surfaces with the right coating to ensure the ink can effectively bond, delivering excellent results every time.

3. Is Natural Leather with Non-Synthetic Composition Suitable for Sublimation?

Natural leather, while a high-quality material, is not suitable for sublimation printing. The surface of natural leather is often irregular and porous, and it lacks the ability to absorb sublimation ink evenly. This makes it difficult to achieve a consistent, clear image, and the ink will often appear faded or distorted on the leather.

In contrast, sublimation leatherette patches use synthetic materials such as polyurethane (PU) and PVC, which are specially treated to be compatible with sublimation printing. These materials offer a smooth, consistent surface for ink absorption, ensuring vibrant and precise prints. Yancheng Supernova’s sublimation leatherette patches are made from high-quality synthetic leather, providing an ideal surface for sublimation that is not only visually appealing but also durable.

4. Are Low-Quality or Inferior Synthetic Materials Suitable for Sublimation?

While most synthetic materials are compatible with sublimation printing, some low-quality or inferior synthetic materials may not be ideal for the process. These materials may have inconsistent surface treatments or subpar manufacturing processes, which can result in poor ink adhesion and inferior print quality.

Choosing high-quality synthetic materials is crucial. Yancheng Supernova’s sublimation leatherette patches are made from premium synthetic leather materials, rigorously tested for quality. Our patches are guaranteed to deliver excellent sublimation results, with colors that are vibrant and long-lasting.

5. Are Materials That Cannot Withstand High Temperatures Suitable for Sublimation?

Sublimation printing requires high temperatures to vaporize the ink and transfer it to the material. Certain materials that cannot withstand these temperatures may warp, melt, or be otherwise damaged during the sublimation process. For instance, some plastics, foam materials, or soft rubber might not be able to endure the heat required for sublimation, which could result in distortion or product failure.

While many plastic materials can be used for sublimation, materials with low heat resistance should be avoided. Yancheng Supernova’s sublimation leatherette patches are specifically designed to endure the high temperatures needed for sublimation, ensuring that the printing process proceeds smoothly and the final product remains intact.

6. Are Uneven or Porous Surfaces Suitable for Sublimation?

Some surfaces are uneven or have a porous texture, such as certain types of wood or fabric. These surfaces can affect the even distribution of sublimation ink, causing blurry or uneven results. Fabrics with irregular pore distribution, for example, may cause the print to look unclear or poorly executed.

In contrast, Yancheng Supernova’s sublimation leatherette patches provide a uniform surface that ensures the sublimation ink penetrates evenly. This results in clear, sharp, and vibrant designs with excellent color accuracy, making it ideal for custom products that require precision.

7. Are Materials That Are Too Thick or Too Thin Suitable for Sublimation?

The thickness of a material also plays a role in sublimation printing. If a material is too thick, the heat may not be able to penetrate evenly across the surface, leading to uneven printing or poor results. On the other hand, if the material is too thin, it may deform or warp due to excessive heat exposure during the sublimation process.

Yancheng Supernova’s sublimation leatherette patches are manufactured with precise thickness control, ensuring that they can handle the necessary temperatures for sublimation without compromising the final print quality. Our patches are designed to provide the ideal thickness for consistent, high-quality printing results.

What Are the Technical Challenges in the Production of Sublimation Leatherette Patches?

Sublimation Leatherette Patches have become increasingly popular in the custom market in recent years. These materials combine excellent print quality with durability, making them widely used for various customized products such as accessories, office supplies, gifts, and personal items. However, the production of sublimation leatherette patches is not a straightforward task. The entire production process involves multiple technical steps, each with its own set of challenges. As a company specializing in sublimation and laser technologies, Yancheng Supernova Digital Science & Technology Co., Ltd. has accumulated extensive experience in overcoming these technical difficulties while continuously innovating. This article will explore the technical challenges and difficulties encountered during the production of sublimation leatherette patches from various perspectives.

1. How Does Material Selection and Surface Treatment Affect the Production Process?

One of the key features of sublimation leatherette patches is their unique surface coating. To ensure that sublimation inks adhere well and produce vibrant colors, the material itself must have specific ink absorption characteristics and surface treatment. During the sublimation process, the ink needs to be converted into gas by heat and penetrate the material, forming vivid and durable patterns. If the surface material quality is inconsistent or the coating treatment is uneven, the print quality may suffer, leading to color variation, blurriness, or incomplete patterns.

To ensure the quality of every batch of sublimation leatherette patches, Yancheng Supernova employs advanced surface treatment technologies throughout the production process. This ensures that the material can uniformly absorb the sublimation ink while maintaining vibrant and stable colors. We continuously optimize our coating techniques to solve the issue of coating consistency across different materials, allowing our sublimation leatherette patches to achieve high-quality printing results.

2. How Does Temperature and Time Control Impact the Sublimation Process?

Sublimation printing requires high-temperature heat press equipment to convert the ink into gas and penetrate the surface, and controlling the temperature and time is crucial to ensuring the print quality. If the temperature is too high or too low, or if the heating time is too long or too short, it can result in uneven ink penetration, leading to distorted patterns, fading, or poor adhesion of the ink.

During the production process at Yancheng Supernova, we use advanced sublimation printing equipment and precise temperature control technologies to ensure that temperature and heating time are accurately controlled throughout the entire production cycle. We finely adjust the sublimation parameters for different materials to ensure that every product achieves optimal printing results. Furthermore, our technical team regularly maintains and calibrates the equipment to ensure its high efficiency.

3. What Are the Precision Challenges in Laser Cutting Technology?

Laser engraving and cutting are critical steps in the production of sublimation leatherette patches, especially when custom shapes and patterns are required. Precision in laser cutting is essential. While traditional laser cutting technology can achieve accurate cuts, it can encounter issues such as overheating, deformation, or burn marks when processing sublimation leatherette patches due to the material’s unique nature, which can impact the final appearance and quality of the product.

To address this challenge, Yancheng Supernova has invested in advanced laser engraving equipment and utilizes precise laser control technology to ensure that each cut is accurate and precise. Our laser cutting technology effectively prevents overheating and deformation, ensuring that the product edges are smooth and neat, without affecting the sublimation print quality.

4. How Do We Ensure Consistency and Quality Control in Mass Production?

In mass production, ensuring consistency in quality across all sublimation leatherette patches is a significant challenge. Even small deviations in temperature or time can result in inconsistent quality in a batch, ultimately affecting customer satisfaction.

To solve this issue, Yancheng Supernova has implemented a strict quality control system throughout the production process. We are equipped with automated testing devices that monitor every stage of production, including surface coating, sublimation printing, and laser cutting, ensuring that each batch of products meets our high standards. In addition, we conduct random inspections on a regular basis to ensure that product quality remains consistent throughout the production cycle.

5. How Do We Address the Challenge of Custom Design and Production Flexibility?

With the increasing demand for personalized products, customers’ requirements for designs and specifications have become more diverse. For sublimation leatherette patches, custom designs usually involve a wide range of sizes, shapes, patterns, and colors, which presents a challenge for production flexibility.

At Yancheng Supernova, we rely on flexible production lines and advanced digital design platforms to quickly respond to customer customization needs. Our production equipment supports a variety of custom options, from personalized patterns to precise product size cutting. We provide highly customizable solutions for every order, and our design and technical teams work closely to ensure that every customized order is produced smoothly.

6. How Do Environmental Factors Affect the Sublimation Process?

The sublimation process is sensitive to environmental factors such as temperature and humidity. Excessively high or low humidity can affect the evaporation and adhesion of the ink, while large fluctuations in temperature can affect the stability of sublimation. In areas with high humidity or significant temperature differences, sublimation production may face unstable issues.

To address this challenge, Yancheng Supernova’s production workshops are equipped with advanced temperature and humidity control systems to ensure environmental stability. Additionally, we have developed production parameters tailored to different climate conditions, ensuring stable sublimation production in any environment.

7. How Do We Meet the Challenge of Quick Turnaround for Diverse Customer Needs?

In the custom industry, customer requirements are often highly personalized, and product delivery times are critical. The challenge lies in how to meet customer demands for fast turnaround while maintaining product quality.

Yancheng Supernova, with years of accumulated production experience and strong supply chain management capabilities, is able to deliver orders quickly while ensuring high quality. We have optimized our production processes and enhanced production efficiency through refined management and automation, enabling us to complete large volume orders in a shorter time frame and meet customers’ urgent delivery requirements.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634