Why is Sublimation Key to Durable Leatherette Accessories?

The rising demand for high quality, personalized Personal Accessories in the global market is increasingly being met by products that successfully marry advanced material science with sophisticated digital printing techniques. Central to this innovation are Sublimation Leatherette Keychains and Personal Accessories, which represent a technological leap from traditional printing methods. The exceptional long lasting quality and aesthetic fidelity of these items are directly attributable to the specialized nature of the durable synthetic leather and the unique molecular dynamics of the vibrant sublimation heat transfer process.

The Polymer Science of Durable Synthetic Leather

The foundation of these accessories is a meticulously engineered durable synthetic leather, which serves as a superior, cruelty free, flexible alternative to natural leather. This material is designed not only to withstand the stresses of everyday carry but also to be chemically receptive to sublimation dyes. Natural leather is incompatible with sublimation because it lacks the necessary polymer structure and cannot survive the high heat required without severe damage. The leatherette, conversely, is typically constructed from a blend of polyester and polyurethane materials, which are precisely the polymers necessary for successful heat transfer printing.

The surface of this durable synthetic leather is engineered with a high concentration of polyester based receptors. This polymeric coating is the key ingredient that allows the product to achieve its defining characteristics: fade resistant and scratch proof designs. This polymer layer is highly resistant to abrasion and chemical degradation, giving the leatherette material a robust structure capable of protecting the embedded design from the wear and tear of keys, coins, and general handling. Furthermore, this carefully manufactured substrate offers heat resistance up to 120°C, a crucial property that guarantees the accessory maintains its integrity during the intense thermal environment required by the printing process, ensuring lasting durability.

Understanding the Vibrant Sublimation Heat Transfer Mechanism

The molecular mechanism of vibrant sublimation heat transfer is what sets these accessories apart from surface printed items. The process is defined by a complete phase change of the ink, from solid to gas, bypassing the liquid state entirely.

First, the desired vivid logos, photos, or text are printed using specialized disperse dyes onto a temporary transfer paper. This ink remains stable until it is subjected to temperatures typically around 200°C within a heat press. When this temperature is reached, the dye molecules vaporize into a gaseous state. Simultaneously, the polymer molecules in the durable synthetic leather coating undergo a temporary change; the heat causes the polymer chain to expand slightly, opening up microscopic pores in the material.

The gaseous dye molecules are then driven by pressure and concentration gradients to penetrate deeply into these open polymer pores. This penetration is not a surface coating; it is a molecular infiltration. As the heat source is removed and the accessory cools down, the polymer chains contract and the pores close, trapping the dye molecules inside the solid polymer structure. The dye is now chemically bonded to the material at a depth, rather than simply sitting on top. This depth of integration is why the resulting images boast high color saturation and are intrinsically fade resistant. Since the image is literally inside the material, it becomes inherently scratch proof, as the scratch would need to remove a layer of the material itself to damage the print, not just an external layer of ink. This is a crucial functional advantage for high use items like keychains, luggage tags, and phone wallets.

Functional Integrity and Enhanced Features

Beyond the decorative qualities, the physical construction and supplementary components of these Personal Accessories are optimized for practical everyday carry. The inherent flexible alternative nature of the leatherette allows it to be bent and twisted without cracking, which is essential for items that are frequently handled and stored in pockets or bags.

Functional elements like robust metal hardware for keychains and luggage tags are carefully selected to complement the lasting durability of the leatherette. These metal components must resist corrosion and mechanical failure to ensure the accessories do not detach from the items they are meant to secure. Furthermore, many accessories feature added practical textures. The application of non slip textures on the back of phone wallets, for instance, enhances grip, minimizing the risk of accidental drops. For passport holders, this non slip quality ensures the document remains securely in place during travel.

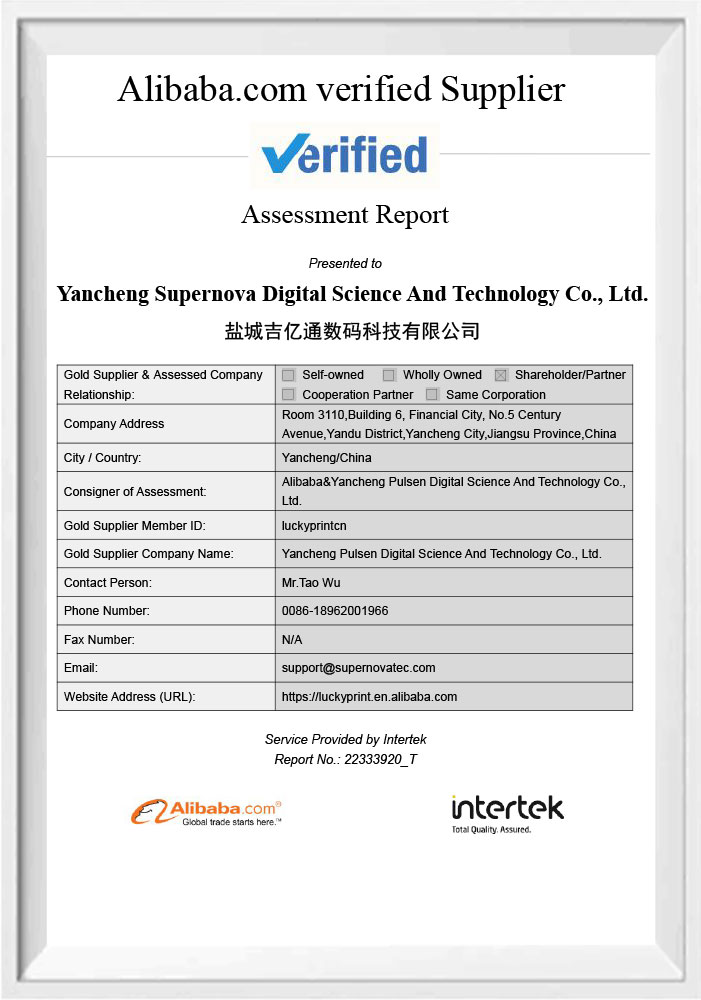

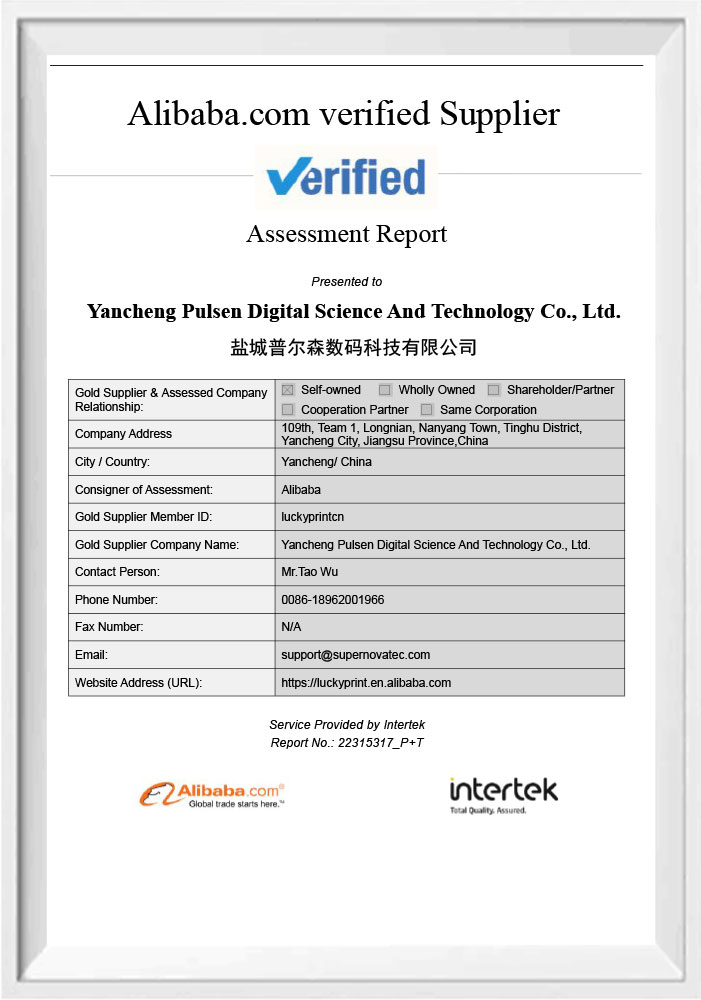

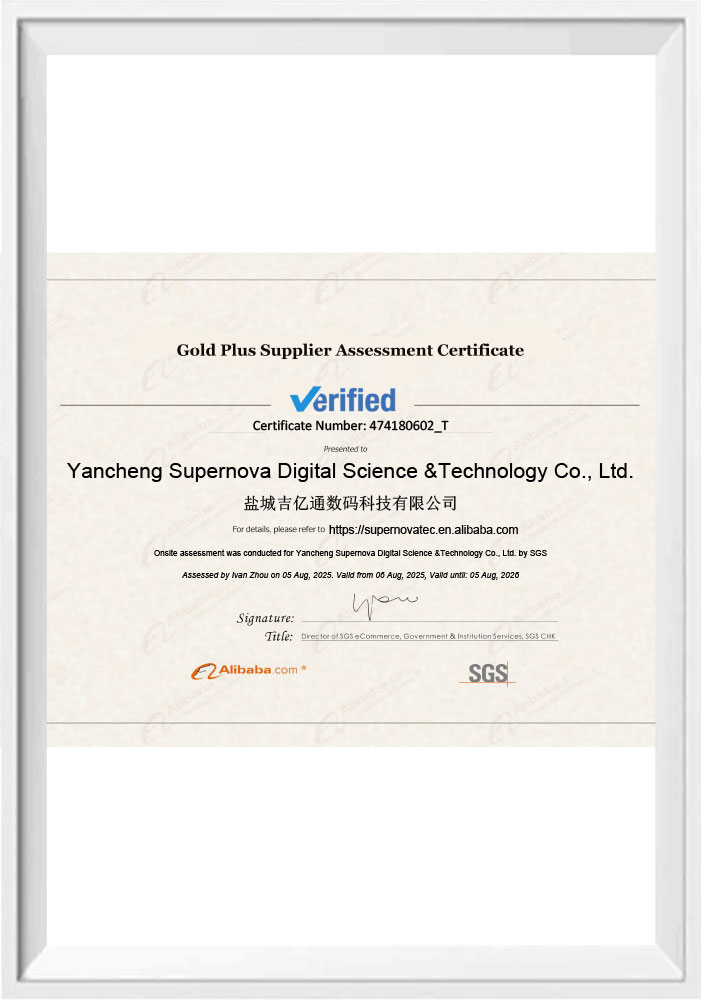

The overall quality management, from raw material sourcing to the final pressing parameters, is key to the industry's success. Companies that specialize in providing these foundation materials, such as Yancheng Supernova Digital Science & Technology Co., Ltd., which has been committed to the research, development, and production of sublimation blanks since its establishment in 2009, ensure that the leatherette substrates are consistently manufactured to accept the sublimation dye perfectly, which is paramount for achieving the consistent, high definition, scratch proof designs demanded by global markets. This rigorous approach to material science and vibrant sublimation heat transfer is the foundational reason these products offer such remarkable quality and longevity.

How Do Custom Shapes Boost Promotional Gifting Value?

The economic viability and market popularity of Sublimation Leatherette Keychains and Personal Accessories stem from their profound versatile nature and their capacity to serve highly specific customization needs. These products efficiently bridge the gap between mass producible promotional items and truly bespoke personalized gifts, thereby offering significant value to both corporate clients seeking custom branding and individuals pursuing memorable gifting. The adaptability in form and function transforms simple items into powerful marketing tools and cherished personal possessions.

Versatility in Product Line and Function

The leatherette material is not confined to a single product type; its adaptability allows manufacturers to produce an expansive range of Personal Accessories designed for everyday carry. This extensive product line significantly broadens the potential market applications. Core products include:

Keychains: Perhaps the most ubiquitous item, used constantly and serving as a persistent reminder of a brand or memory.

Luggage Tags: Essential for travelers, offering a highly visible platform for personalization and business information.

Phone Wallets: Modern and highly functional accessories that adhere to the back of mobile devices, merging convenience with branding space.

Passport Holders: Offering a premium feel and superior protection for travel documents, perfect for high end corporate promotional giveaways.

The versatile nature of the blanks allows for intricate design elements that enhance functionality. For example, phone wallets often use specialized adhesive backing for secure attachment, while luggage tags feature robust detachable clips for ease of transfer. Passport holders and other stitchable items utilize specialized stitchable edges that allow for professional finishing and assembly, contributing to the overall long lasting quality of the accessory.

Deep Customization and Aesthetic Flexibility

A major driver of market demand is the ability to leverage custom shapes and sizes. Unlike traditional printing on prefabricated goods, sublimation blanks can be precision cut to virtually any specification, including round, oval, and rectangular forms, as well as highly specialized, non standard silhouettes. This geometric freedom is crucial for custom branding efforts where a company logo or mascot has a unique outline that must be precisely replicated for maximum impact. The combination of vivid logos, photos, or text with a perfectly matched custom shape creates a cohesive and professional presentation for promotional giveaways.

The ability to easily manage both vast bulk orders for major corporate events and small batch specialized DIY projects demonstrates the efficiency of the sublimation production chain. This scalability allows the same high quality, fade resistant and scratch proof designs to be applied across millions of units for a global brand or a single, sentimental item for a milestone birthday. This flexibility makes the product accessible to every tier of the market, from multinational corporations to local crafters.

Market Applications: Gifting and Corporate Branding

In the realm of personal use, these accessories excel as personalized gifts for life events. The durability and aesthetic quality of the durable synthetic leather elevate a simple gift into a lasting keepsake. For occasions like birthdays, graduations, or anniversaries, the ability to embed a unique message or a cherished photograph ensures the gift is truly memorable gifting. The cruelty free nature of the leatherette also appeals to a growing segment of consumers who prioritize ethical sourcing in their purchases.

For the corporate sector, these items are a strategic investment in brand presence. Used as promotional giveaways, they offer a high perceived value that reflects positively on the brand. For instance, an airline might provide luggage tags to its premium passengers, or a financial institution might use phone wallets with their vivid logos for client onboarding. The fact that the design is permanent means the brand exposure is maintained throughout the life of the accessory, providing a long term return on investment compared to disposable promotional materials. The superior high color saturation ensures that brand guidelines for color integrity are perfectly met, maintaining brand consistency across all products.

The industry surrounding these sophisticated products is sustained by innovators specializing in the foundational blanks. Companies focused on the research, development, and production of sublimation blanks and laser blanks are fundamental to maintaining supply chain quality. They ensure that manufacturers have access to the materials necessary to execute precise heat transfer printing. This dedication to material advancement allows for the continued creation of highly functional and aesthetically pleasing accessories that are perfect for both everyday carry and memorable gifting, driving forward the value proposition of this important segment of the customization market.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634