How Does the Fusion of Sublimation Technology and Durable Materials Ensure Lasting Quality and Aesthetic Fidelity in Coasters?

The modern market for customized home goods and promotional items demands a fusion of high aesthetic quality with practical longevity. In this landscape, Sublimation Coasters have emerged as a superior product, defining a new standard through the clever integration of vibrant sublimation heat transfer technology and carefully selected durable materials. These coasters are not merely functional accessories; they are permanent canvases for personalized decor and effective tools for brand building. Understanding their inherent quality requires a detailed look into the science of their decoration and the engineering of their substrates.

The Mechanism of Vibrant Sublimation Heat Transfer

The core innovation driving the quality of these products is the vibrant sublimation heat transfer process itself. Unlike conventional methods of printing, which involve applying liquid ink to the surface of a material, sublimation operates on a molecular level, establishing a truly permanent bond. The process begins with the print phase, where specialized sublimation inks are printed onto transfer paper. The key transformation occurs during the heat application phase, typically involving a heat press at temperatures around 200°C. At this temperature, the solid dye converts directly into a gas, bypassing the liquid state entirely. This gaseous dye is then able to penetrate the polyester coating or polymer-infused fibers of the substrate.

As the material cools, the dye reverts to its solid state, becoming permanently embedded within the structure of the coaster itself. This deep integration is the reason why these coasters achieve such high color saturation and impressive detail. The colors are not a layer susceptible to flaking, scratching, or washing off; rather, they are part of the material. This distinction is critical to the coaster's durable materials classification, ensuring that the vivid logos, photos, or text applied are as resilient as the material itself. The result is a design that is exceptionally fade resistant and capable of withstanding the rigors of daily use, from frequent washing to prolonged exposure to light.

Material Science and Functional Durability

The performance of Sublimation Coasters is fundamentally reliant on the selection of robust, receptive materials. The industry utilizes several substrates, including leatherette, acrylic, and ceramic, each chosen for its unique blend of aesthetic appeal and functional performance, particularly its compatibility with heat transfer printing.

Leatherette Coasters represent a sophisticated choice, offering a tactile, elegant finish that often mimics the texture of genuine leather. This material is lightweight yet highly resilient, making it a popular option for executive promotional gifts and upscale personalized decor. Its polymeric surface is engineered for optimal dye absorption, ensuring the sublimated images are crisp and deeply integrated. Furthermore, the material naturally includes non slip backs in many configurations, adding stability and protecting surfaces from scratches.

Acrylic Coasters provide a modern, sleek aesthetic. Known for their clarity and high impact resistance, acrylic substrates are ideal for displaying intricate designs with a glass like depth. They appeal to the contemporary design market where a clean, sharp visual is paramount. Acrylic's consistent surface allows for predictable and flawless heat transfer printing, and its inherent durability means it can withstand repeated drops and heavy handling, often preferred in office or commercial environments.

Ceramic Coasters are the standard bearer for traditional high heat resistance. Ceramic offers a classic, weighty feel and an extremely hard surface. While heavier, their porous, yet coated, structure is perfectly suited for absorbing the gaseous dyes, resulting in rich, deep colors that are truly permanent. Their structural integrity ensures they can handle mugs and coffee cups straight from brewing without degradation to the coaster or transfer of heat to the underlying surface. This material is particularly favored in hotel and cafe settings where high traffic and frequent use of hot beverages are the norm.

Regardless of the material chosen, the integration of non slip backs, typically made of cork or a soft foam rubber, is a mandatory feature. This simple addition ensures the coaster remains firmly in place, mitigating the risk of spills and further enhancing its role in table protection. The success of Sublimation Coasters is therefore a testament to the seamless collaboration between the precise art of sublimation and the proven performance of these durable materials.

Quality Assurance and Environmental Responsibility

To guarantee consistent product quality, manufacturers focus on strict parameters for material sourcing and process control. The temperature of the press, the dwell time, and the pressure applied must be meticulously controlled to achieve perfect dye penetration and high color saturation without damaging the substrate. This technical discipline is what allows for the scalability of production to meet demanding bulk orders while maintaining the quality expected for a single DIY project.

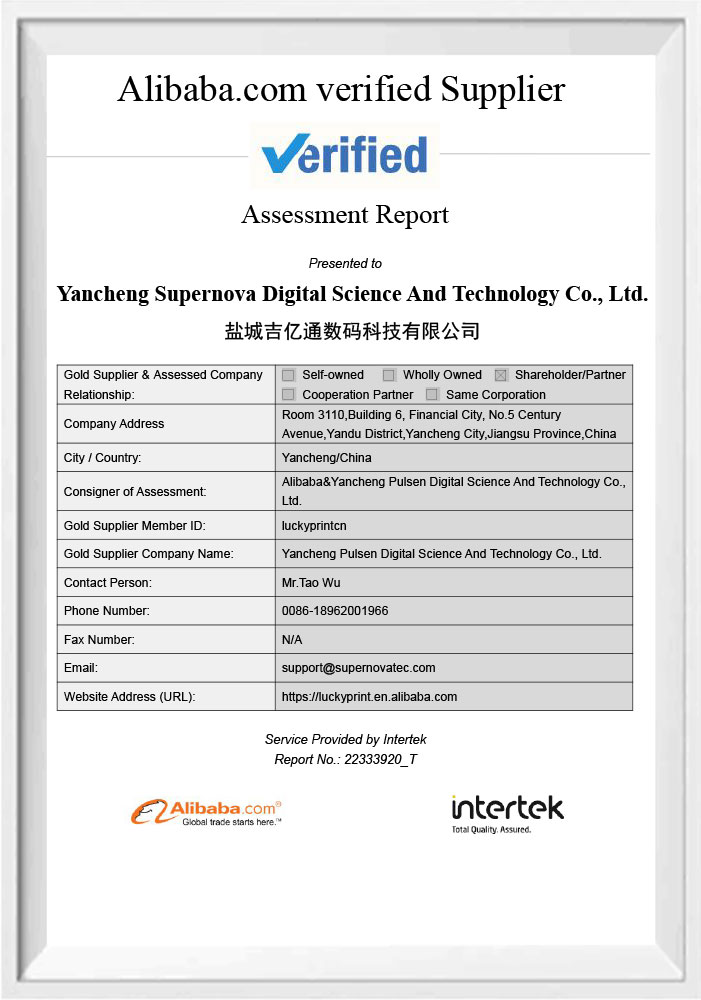

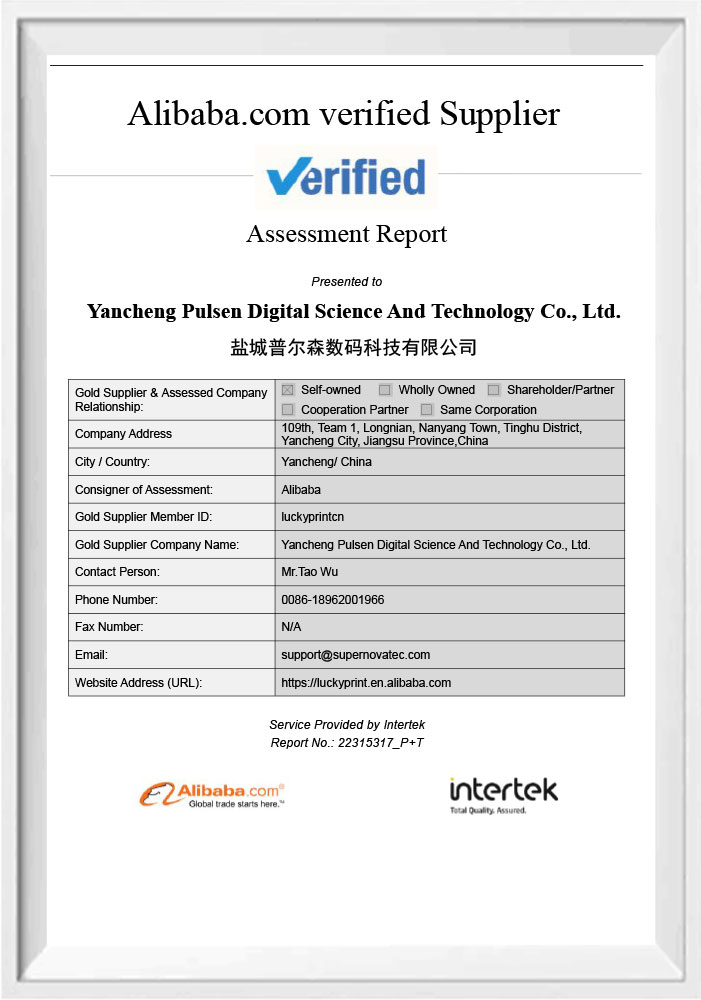

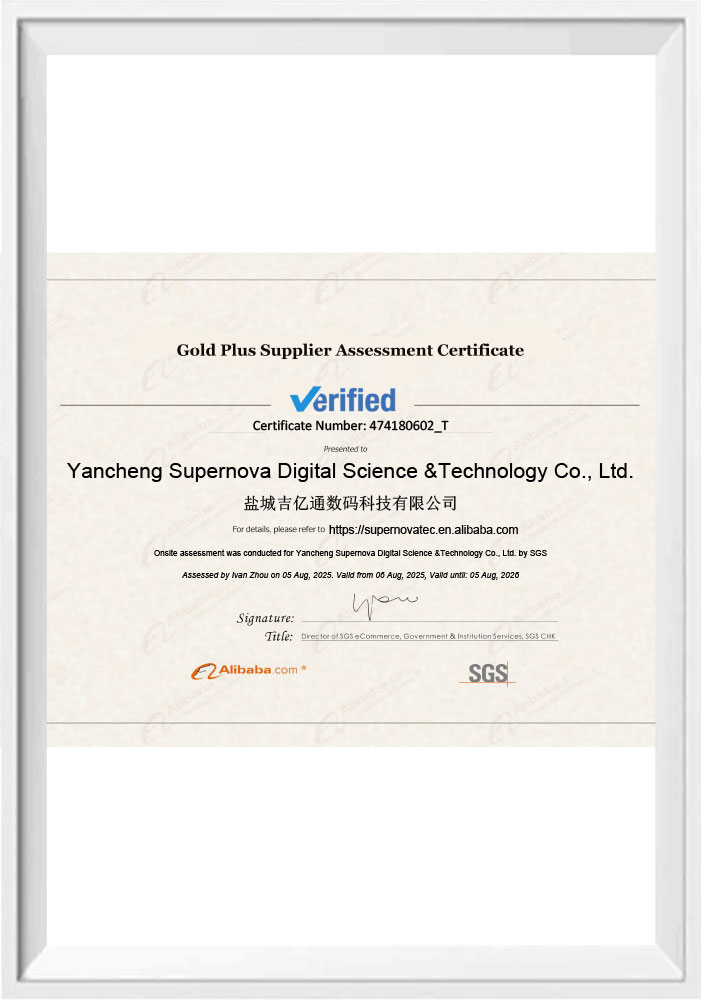

Furthermore, the longevity inherent in the permanent designs and durable materials contributes to a more eco-friendly product profile. By creating items that last for years without fading or peeling, the need for frequent replacement is drastically reduced. This commitment to enduring quality supports sustainable consumer practices, adding another layer of value for the environmentally conscious buyer. In the early stages of its development, this industry relied on pioneering companies to perfect the process. Yancheng Supernova Digital Science & Technology Co., Ltd., established in 2009, is a notable example, playing a key role as a China Sublimation Coasters Manufacturers and Sublimation Coasters Suppliers specializing in the research, development, and production of the necessary sublimation and laser blanks that enable this sophisticated level of quality and customization globally.

In What Ways Do Customization and Versatility Transform Sublimation Coasters into a High Value Tool for Personalization and Brand Promotion?

The economic and emotional value proposition of Sublimation Coasters is rooted in their exceptional versatile nature and their capacity for deep customization. They transcend their basic function as protective tools to become a high value communication medium, equally effective for creating cherished personalized decor in a private home or serving as powerful promotional gifts in a corporate setting. This transformation is driven by the flexibility offered by heat transfer printing and the adaptability of the available substrates.

Elevating Personal Decor and Gifting

For individual consumers, the appeal of Sublimation Coasters lies in the ability to create truly one of a kind items that reflect personal milestones, memories, or artistic tastes. The freedom to apply vivid logos, photos, or text allows these items to integrate seamlessly into a person's living space, moving beyond simple utility.

The personalization extends across various life events:

Weddings and Anniversaries: Coasters can be printed with engagement photos, wedding dates, or a couple's monogram, serving as meaningful party favors or thank you gifts. The permanent nature of the print ensures the memory lasts.

Family Keepsakes: Customers frequently use heat transfer printing to display portraits of children or pets, turning functional home items into emotionally resonant personalized decor. The exceptional high color saturation preserves the vibrancy of these cherished images.

DIY Projects: The ease of use of sublimation blanks makes them a favorite among crafters and hobbyists who engage in DIY projects. They offer a professional result with relatively accessible equipment, providing a rewarding way to create unique, handcrafted gifts for friends and family. The availability in custom shapes and sizes, such as round, square, or oval, further fuels creative design options.

This power of creation means that the final product's value far surpasses the cost of its materials and production. It embodies sentimental value, transforming a simple piece of leatherette, acrylic, or ceramic into a valuable memento.

Strategic Use in Brand Promotion and Corporate Identity

In the commercial sector, Sublimation Coasters are recognized as highly effective promotional gifts due to their visibility, utility, and durable materials. They offer continuous, subtle brand exposure in environments where decisions are often made.

For businesses, the advantages are multifold:

Constant Visibility: Placed on desks, conference tables, or in hotel rooms, the coaster is a daily touchpoint for the brand. Unlike a promotional pen tucked in a drawer, a coaster is always out, ensuring the vivid logos, photos, or text are consistently seen.

Perceived Quality: Using materials like premium leatherette or polished acrylic ensures that the promotional gifts convey an image of quality and professionalism. The superior performance, including strong heat resistance and non slip backs, reinforces the idea that the company invests in high quality details.

Targeted Customization: Businesses can leverage custom shapes and sizes to align with specific marketing campaigns or product launches. For instance, a tech company might order an acrylic coaster in the shape of a gear, while a winery might opt for an oval ceramic design. The ability to handle bulk orders efficiently ensures that large scale events and trade shows can be adequately supplied with consistent, high quality merchandise.

Hotels and cafes utilize them to enhance their hospitality branding. Coasters customized with the establishment's aesthetic serve as part of the overall personalized decor and often double as take away souvenirs for guests. This is a practical application where the durable materials and permanent printing are essential for longevity in high traffic commercial settings.

Scalability and Market Future

The market's ability to support both intimate DIY projects and large scale bulk orders is a key indicator of the industry's robustness. The manufacturing process is highly scalable, allowing for efficient production of thousands of units without compromising on the quality of the vibrant sublimation heat transfer or the finish of the durable materials.

Looking forward, the demand for versatile and eco-friendly personalized products is only projected to grow. Consumers are increasingly seeking items that offer functional utility alongside deep personalization. Sublimation Coasters, with their proven track record of aesthetic quality, superior heat resistance, and permanent decoration, are perfectly positioned to capture this expanding market share. Their ability to serve as a low cost, high impact marketing tool for businesses and a meaningful item for individuals ensures their sustained relevance in the decorative and promotional goods sector. The continuous innovation in substrate formulation and printing techniques will only further cement the coaster's status as a staple for both functional protection and bespoke design.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634