What Are the Main Advantages of Leatherette Sheet Stock Compared to Natural Leather?

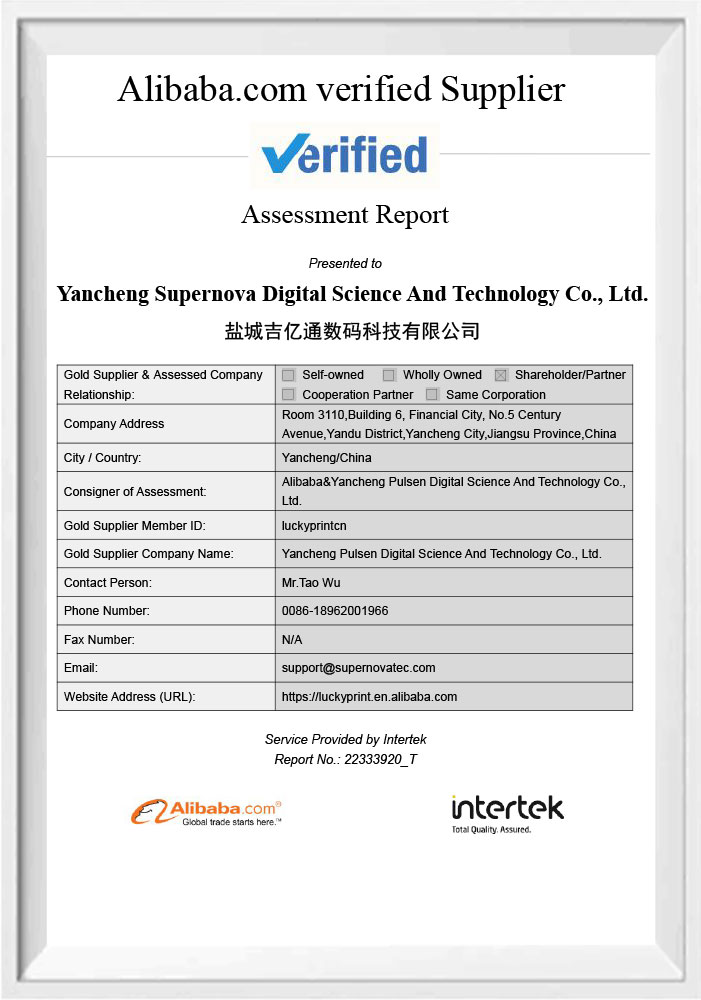

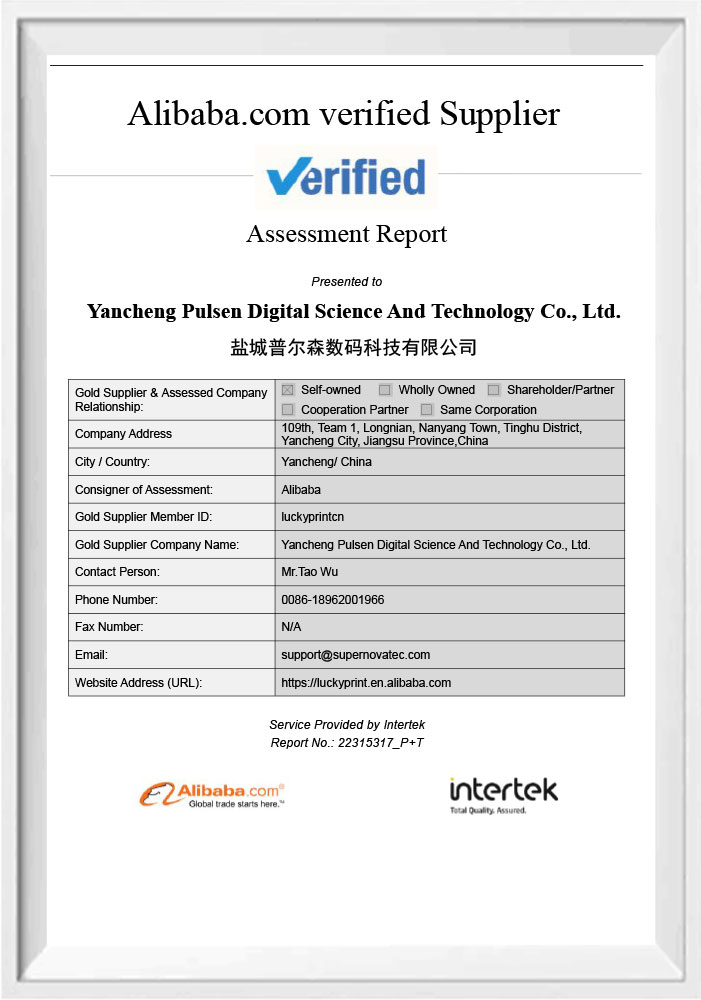

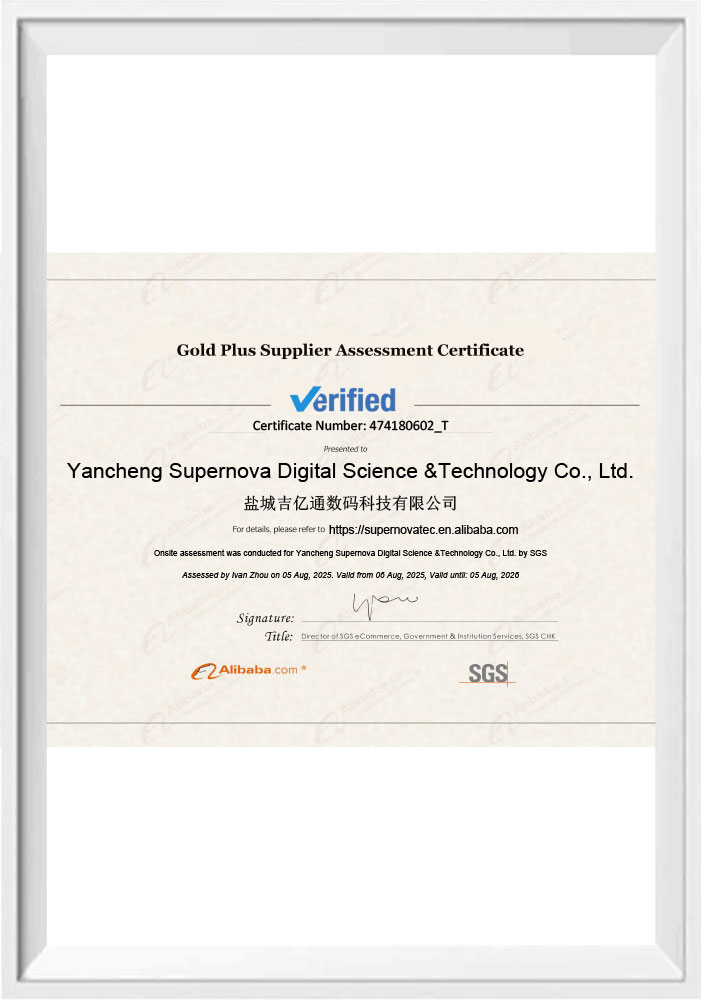

As the demand for eco-friendly materials and high-cost performance products increases, Yancheng Supernova Digital Science & Technology Co., Ltd. is dedicated to providing high-quality Laserable Leatherette products, which resemble the appearance and feel of natural leather while offering several unique advantages. Our Leatherette Sheet Stocks are widely used in office accessories, fashion accessories, customized gifts, and other fields, with outstanding product performance ensured through innovative manufacturing techniques.

1. Price Advantage

One of the most significant advantages of Leatherette compared to natural leather is its price. Natural leather requires complex production and processing techniques, and due to its rarity and limited resources, its cost is higher. In contrast, Leatherette is made from synthetic materials like PVC and other resins, allowing for large-scale production and significantly reducing costs. For customers who need to produce large quantities of customized products, Leatherette is undoubtedly a more cost-effective choice.

2. Environmental Friendliness

The production process of natural leather often involves the use of a large number of chemical dyes and tanning agents, which can cause environmental pollution. In contrast, Leatherette uses more environmentally friendly synthetic materials and dyes and does not involve the use of animal leather. This makes Leatherette the preferred material for environmentally conscious consumers and businesses.

3. Customizability

The Leatherette Sheet Stocks provided by Yancheng Supernova Digital Science & Technology Co., Ltd. offers exceptional customizability, allowing for precise engraving of various patterns, text, and designs through laser engraving technology. Natural leather, however, has limitations in terms of customizability due to its texture and thickness, and the processing difficulty is higher. With our technology, customers can easily achieve high-precision custom effects, meeting the demand for personalized products.

4. Durability and Maintenance

While natural leather is loved for its natural texture and unique patterns, it is also sensitive to environmental factors like moisture, sunlight, and temperature, which require more maintenance and care. Leatherette, on the other hand, boasts better water resistance, abrasion resistance, and stain resistance, making it suitable for a broader range of environments, and maintenance is relatively simple. With regular cleaning and proper care, Leatherette can maintain its good appearance and performance over a long period.

5. Consistency and Stability

Natural leather, sourced from different animals, often has natural textures and imperfections, which can affect the overall appearance and consistency of the product. In contrast, Leatherette is produced through synthetic processes, ensuring that each sheet has high consistency, with stable quality in terms of texture, color, and thickness.

6. Weather Resistance

Leatherette performs excellently in terms of weather resistance, effectively resisting the impact of UV rays, humidity, and temperature fluctuations without fading or warping. This gives it an advantage over natural leather when used in outdoor and high-humidity environments. For example, when used in indoor decorations or outdoor products, Leatherette can maintain its appearance and withstand the test of time.

How to Ensure Clean and Neat Edges Without Fraying When Laser Engraving and Cutting Leatherette Sheet Stock?

Ensuring clean and neat edges without fraying when laser engraving and cutting Leatherette Sheet Stock is a key challenge in the processing of this material. Laser technology provides precise control for the fine cutting of Leatherette, but it requires accurate craftsmanship and parameter adjustments to achieve the best results. As Yancheng Supernova Digital Science & Technology Co., Ltd.'s manufacturer, we continuously optimize laser cutting technology to ensure that each Leatherette sheet has clean, neat edges with no fraying after laser processing.

1. Basic Principle of Laser Cutting and Engraving

Laser cutting and engraving technology rely on high-powered laser beams to precisely process materials. The laser beam heats the material to the point of melting or ablating, achieving cutting and engraving. For materials like Leatherette, excessive heat can cause edge melting or charring, so precise control of laser power, cutting speed, and processing paths is crucial to avoid such issues.

2. Appropriate Laser Power and Speed Adjustment

Different thicknesses and types of Leatherette materials require different laser power and cutting speed. Too high a laser power can lead to excessive melting at the edges, resulting in charring or fraying, while too low power can lead to incomplete cuts or rough edges. By precisely adjusting laser power and cutting speed, Yancheng Supernova Digital Science & Technology Co., Ltd. ensures that each Leatherette material’s edges are neat, smooth, and free of fraying.

3. Use of High-Precision Laser Equipment

Our company uses advanced laser cutting equipment that achieves extremely high precision in cutting. These devices have precise laser beam control systems, allowing for detailed engraving and cutting on various Leatherette materials, ensuring that the edges are clean, smooth, and free of fraying or melting.

4. Material Selection and Treatment

Yancheng Supernova Digital Science & Technology Co., Ltd. selects high-quality Leatherette materials for laser processing. These materials have a smooth surface and better heat resistance and toughness, making them less likely to suffer from edge melting or fraying during laser processing. Additionally, we have established specific processing parameters for different types of materials to ensure that each batch of materials achieves consistent high standards in terms of cutting quality.

5. Post-Processing Techniques

After laser cutting, we further improve the cutting effect through specialized post-processing techniques. Using appropriate tools to clean the cutting surfaces, we remove any residual burrs or molten debris to ensure that the edges are smooth and free of fraying. This process enhances the appearance and usability of Leatherette products.

How to Clean and Maintain Leatherette Sheet Stock to Ensure Long-Term Good Condition?

Leatherette, as a synthetic leather material, is highly durable and easy to maintain, making it the ideal choice for many customized products and everyday items. However, to ensure that Leatherette maintains its good appearance and performance over time, proper cleaning and maintenance are essential. Below are the cleaning and maintenance methods recommended by Yancheng Supernova Digital Science & Technology Co., Ltd.:

1. Regular Cleaning

Regular cleaning is the key step to maintaining Leatherette in its best condition. Use a soft microfiber cloth to wipe the surface regularly to remove dust and dirt. Avoid using rough cloths or abrasive materials to wipe, as they can scratch the material. For stubborn stains, it is recommended to use mild soap water or specialized Leatherette cleaner.

2. Avoid Strong Chemical Cleaners

Although Leatherette materials are durable, they may be sensitive to some strong chemical cleaners. Avoid using cleaners that contain alcohol, ammonia, or strong acidic or alkaline substances, as these may damage the surface coating and cause fading or cracking. When cleaning, it is best to choose mild, Leatherette-specific cleaners.

3. Proper Maintenance

For smoother Leatherette surfaces, you can use a specialized Leatherette conditioner to help restore gloss and prevent cracking and fading. However, before use, it is advisable to test a small area to ensure that it does not affect the color or texture of the material.

4. Prevent Liquid Penetration

Although Leatherette has certain water resistance, prolonged contact with liquid may still damage its surface. If liquid is accidentally spilled on the Leatherette surface, it should be immediately wiped with a clean, soft cloth to prevent the liquid from penetrating into the material.

5. Storage and Usage Environment

Leatherette products should be kept away from prolonged exposure to high temperatures and direct sunlight. Extended exposure can cause the material to discolor or harden, affecting its lifespan. When storing, it is best to place the products in a cool, dry place and avoid contact with sharp objects.

By following the correct cleaning and maintenance methods, Yancheng Supernova Digital Science & Technology Co., Ltd.'s Leatherette products can maintain excellent performance in various applications, providing a longer-lasting user experience and high-quality appearance.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634