Does the Leatherette Office and Tech Accessories Support Multiple Assembly Methods?

Characteristics of Leatherette Office and Tech Accessories

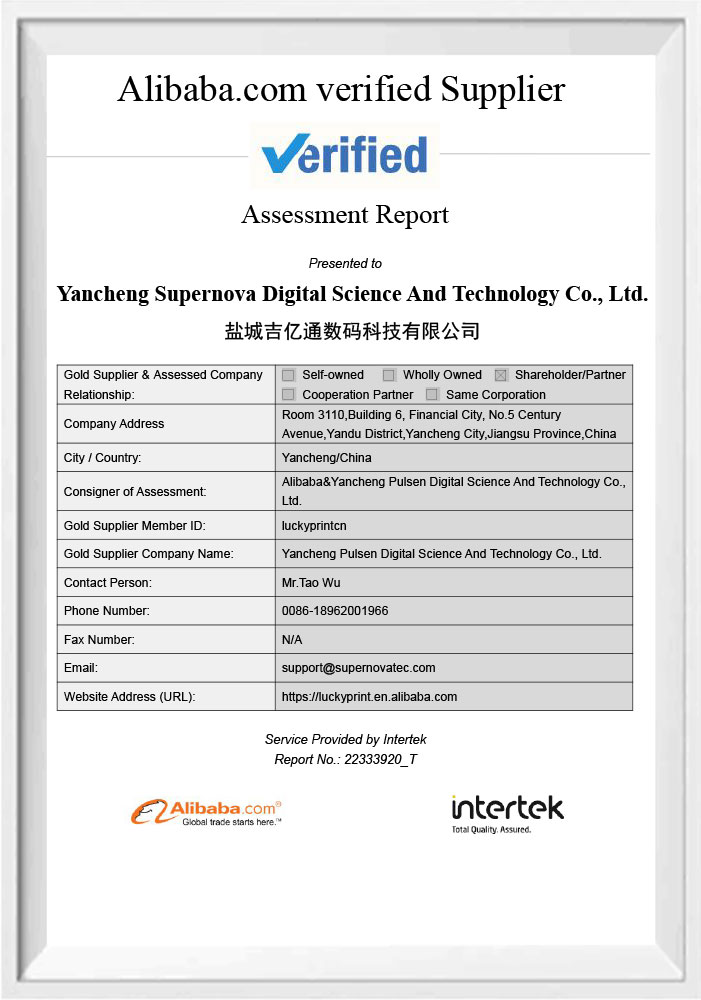

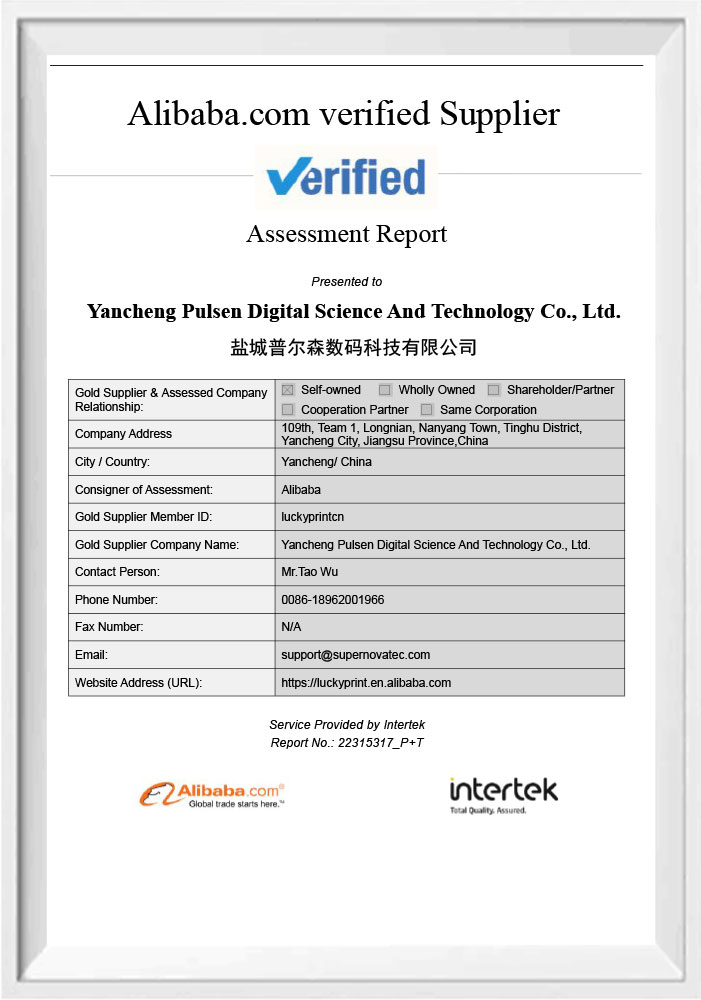

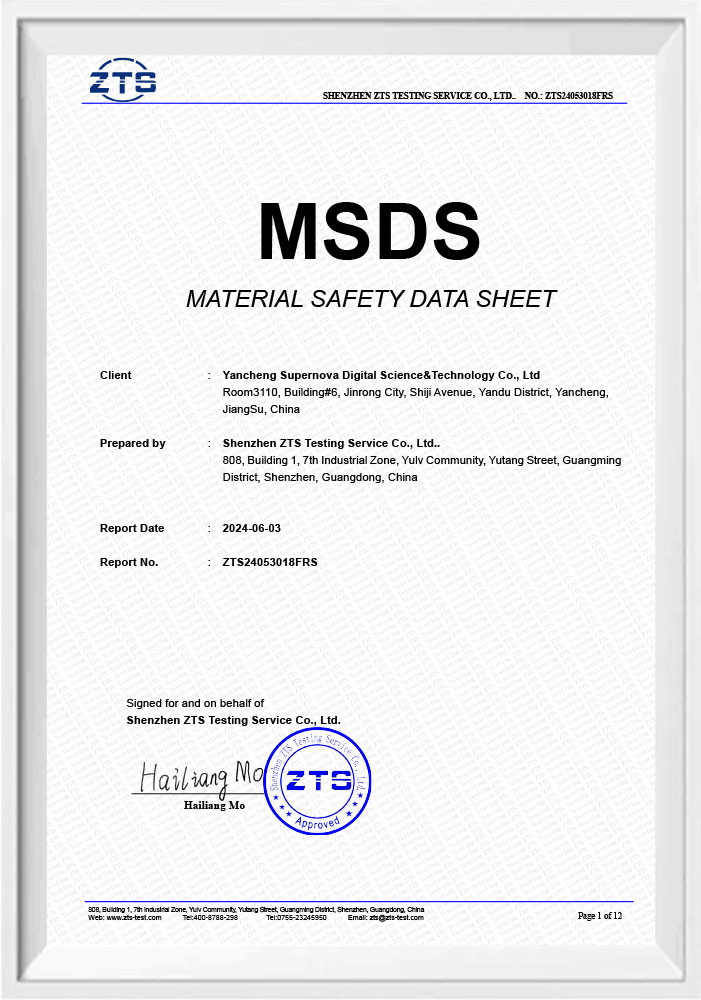

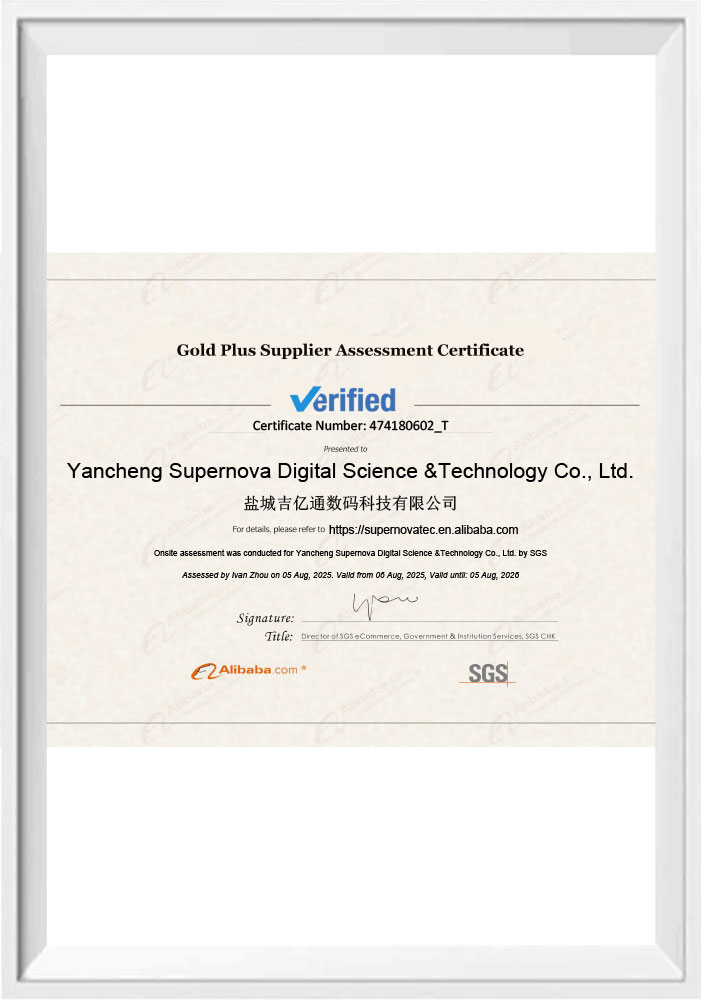

Leatherette office and tech accessories are widely used in workspaces, promotional gifting, and business environments due to their refined appearance, soft texture, and adaptable structure. These accessories include mouse pads, desk organizers, cable wraps, tablet holders, notebook covers, and other functional products designed for daily office use. Yancheng Supernova Digital Science & Technology Co., Ltd., established in 2009, is a professional manufacturer of leatherette keychains, cigar cases, and various personal accessories. The company specializes in sublimation blanks and laser blanks, meaning its leatherette materials are engineered for compatibility with printing and engraving processes. Because leatherette consists of layered synthetic structures, it supports different production and assembly techniques, allowing manufacturers to create diverse and practical office and tech accessories.

Material Composition and Its Influence on Assembly Compatibility

Leatherette materials are typically formed from polyurethane-coated fibers or synthetic composites that replicate the appearance of genuine leather. This structure enhances surface uniformity and gives the material flexibility needed for shaping and assembling different office and tech accessories. Products developed by Yancheng Supernova Digital Science & Technology Co., Ltd. undergo careful material preparation to ensure that they work well with sublimation and laser engraving processes. These requirements also improve compatibility with various assembly methods because materials must maintain dimensional stability and consistent thickness. As a result, leatherette office and tech accessories generally support multiple fastening options, stitching techniques, and adhesive applications without difficulty.

Common Assembly Methods Used in Leatherette Accessories

Many manufacturers adopt several assembly techniques when producing leatherette items, including gluing, stitching, heat pressing, and mechanical fastening. Each method offers different advantages depending on the product’s purpose, expected usage environment, and design. Leatherette’s synthetic structure and stable surface finish make it adaptable to these processes. Companies like Yancheng Supernova Digital Science & Technology Co., Ltd. design their leatherette blanks to meet diverse production needs, ensuring that the material performs reliably whether it is being stitched into covers, glued into rigid forms, or engraved after assembly. These features allow manufacturers to provide various office and tech products with dependable structure and visual consistency.

Stitching and Edge Finishing Techniques

Stitching is one of the most common assembly methods for leatherette office and tech accessories because it provides a stable connection between layers while enhancing visual appeal. The uniform thickness and controlled flexibility of leatherette materials from Yancheng Supernova Digital Science & Technology Co., Ltd. enable smooth stitching and consistent edge finishing. This makes it suitable for notebook covers, tablet sleeves, organizer pockets, and other items that require reinforced edges. Stitching also allows the combination of leatherette with additional materials, such as EVA foam or fabric liners, offering designers freedom to create structured products suitable for office and technology-related uses.

Adhesive Bonding for Structural Stability

Adhesive bonding is frequently used when producing rigid or semi-rigid leatherette accessories like organizers, desk trays, or multi-layered holders. The polyurethane layer of leatherette adheres well to industrial adhesives, allowing secure bonding without altering the surface appearance. Yancheng Supernova Digital Science & Technology Co., Ltd. prepares its leatherette materials to maintain consistent bonding performance, which supports a wide range of office and tech accessory designs. Adhesive bonding also allows faster assembly during mass production and makes it possible to integrate decorative elements, sublimation prints, or laser engravings without affecting structural stability.

Heat Pressing and Thermoforming Options

Heat pressing is often used when producing leatherette items that require clean, shaped edges or embossed patterns. Leatherette responds well to controlled heat, allowing manufacturers to curve or mold the material during assembly. This method is especially useful for items like tablet stands, multi-functional pouches, and cable organizers. Companies specializing in sublimation blanks, such as Yancheng Supernova Digital Science & Technology Co., Ltd., ensure their materials tolerate heat exposure because sublimation printing requires high temperatures. This built-in heat resistance enhances compatibility with thermoforming and heat-press assembly methods, expanding the design possibilities for office and tech accessories.

Mechanical Fastening and Modular Assembly

Mechanical fastening methods such as metal rivets, snaps, screw fittings, or magnetic closures are also suitable for leatherette office and tech accessories. The material’s layered structure provides enough strength to accommodate these components without tearing when properly reinforced. Items like cable wraps, notebook binders, and foldable desk accessories often rely on mechanical fasteners to enhance convenience and adjustability. Yancheng Supernova Digital Science & Technology Co., Ltd. produces leatherette blanks with stable structural properties, supporting these fastening choices during product assembly. This allows manufacturers to create modular or adjustable office accessories that meet varied user preferences.

Common Assembly Methods and Compatible Leatherette Products

| Assembly Method | Suitable Leatherette Products | Key Advantages |

| Stitching | Notebook covers, tablet sleeves, organizers | Reinforced edges, strong attachment |

| Adhesive Bonding | Desk trays, rigid organizers, multi-layer cases | Smooth finish, stable structure |

| Heat Pressing | Embossed items, molded holders, shaped accessories | Clean contours, decorative options |

| Mechanical Fastening | Cable wraps, binder covers, adjustable pouches | Flexibility, reusable attachment |

How Company Expertise Supports Assembly Diversity

Yancheng Supernova Digital Science & Technology Co., Ltd. has extensive experience in developing sublimation and laser blanks, which requires precise material processing. This expertise directly supports the production of leatherette office and tech accessories that accept multiple assembly methods. Consistent surface texture, stable thickness, and controlled flexibility allow the material to adapt to stitching, bonding, heat pressing, and mechanical fastening. This flexibility benefits manufacturers seeking to expand their product lines and ensures that end users receive accessories that function reliably in offices, workplaces, and daily environments.

Can Leatherette Office and Tech Accessories Guarantee Consistent Quality Across All Batches?

Material Stability in Leatherette Office and Tech Accessories

Leatherette office and tech accessories depend on material consistency to maintain a uniform appearance, structural reliability, and smooth surface performance. Leatherette is a synthetic material made through layered production, usually involving polyurethane coatings and textile backings. This layered structure allows it to imitate the look of leather while offering predictable performance. Yancheng Supernova Digital Science & Technology Co., Ltd., founded in 2009, specializes in the research, development, and production of sublimation blanks and laser blanks. Its experience in manufacturing leatherette keychains, cigar cases, and personal accessories contributes to improved stability in material sourcing and preparation. Since sublimation and laser processing require consistent surfaces and controlled material thickness, the company places emphasis on achieving uniform quality across production cycles.

Importance of Controlled Manufacturing Processes

Producing leatherette accessories with consistent quality depends on well-controlled manufacturing processes. These processes include material cutting, surface treatment, printing preparation, and assembly procedures. Yancheng Supernova Digital Science & Technology Co., Ltd. adopts standardized workflows to manage each production stage, ensuring that leatherette surfaces maintain the required smoothness and durability for office and tech accessories. For example, sublimation blanks must maintain consistent heat tolerance, while laser blanks must offer predictable engraving responses. By using controlled production lines and automated equipment where appropriate, the company reduces variations between batches and improves uniformity among finished products.

Batch Quality Control and Inspection Systems

Batch quality control is essential when producing leatherette office and tech accessories, especially for items intended for sublimation printing or laser engraving. The surface must maintain consistent texture and color to avoid unexpected variations that could affect the final appearance. Yancheng Supernova Digital Science & Technology Co., Ltd. implements systematic inspection processes for each production batch, checking factors such as thickness stability, color consistency, coating uniformity, and bonding strength. Inspection stages often include pre-production sampling, in-process monitoring, and final inspection before packaging. These checks help ensure that each batch of leatherette accessories meets company standards and customer expectations.

Influence of Raw Material Selection on Batch Consistency

Raw material quality is one of the most important factors influencing batch consistency. Leatherette components rely on stable polyurethane coatings, reliable textile backings, and adhesives with controlled performance. Yancheng Supernova Digital Science & Technology Co., Ltd. collaborates with long-term suppliers to ensure that raw materials remain consistent across repeated orders. This reduces the risk of unexpected batch differences such as uneven texture, inconsistent firmness, or color variations. Stable sourcing also enhances the reliability of sublimation and laser processing, because these techniques require predictable material behavior during heat exposure and engraving.

Key Factors Influencing Consistent Quality Across Batches

| Factor | Impact on Quality | Company Measures |

| Raw Materials | Affects texture, color, and thickness | Long-term supplier cooperation |

| Production Equipment | Determines cut precision and coating stability | Standardized equipment operation |

| Surface Treatment | Influences engraving and printing performance | Controlled treatment processes |

| Inspection Protocols | Ensures defects are identified early | Batch sampling and final inspection |

Consistency in Surface Texture and Color for Office and Tech Use

For office and tech accessories, consistency in surface texture and color is essential because these products are often used in coordinated sets or business branding applications. Leatherette mouse pads, desk organizers, notebook covers, and cable accessories need to display uniform visual characteristics to create a coordinated appearance. Yancheng Supernova Digital Science & Technology Co., Ltd. uses calibrated color-matching techniques and stable coating processes to maintain batch-to-batch uniformity. The company also monitors temperature and environmental conditions during production to minimize variations caused by humidity or heat fluctuations, contributing to stable material outcomes.

Role of Technology in Improving Product Consistency

Technological applications play a significant role in ensuring that leatherette office and tech accessories maintain predictable performance across batches. Automated cutting machines ensure accurate sizing, while digital coating controls maintain consistent layer thickness. For sublimation blanks and laser blanks, digital systems monitor heat resistance, engraving depth response, and material density. Yancheng Supernova Digital Science & Technology Co., Ltd. integrates these technologies into its production process to enhance consistency. This approach minimizes manual deviations and provides a reliable foundation for producing large quantities of leatherette accessories with stable quality.

Customer Confidence through Reliable Batch Performance

Reliable batch performance helps manufacturers build customer confidence, especially when customers require consistent products for branding, gift customization, or bulk orders. Because Yancheng Supernova Digital Science & Technology Co., Ltd. specializes in sublimation blanks and laser blanks, the company understands the importance of predictable material behavior for engraving and printing applications. By maintaining strict quality management, stable raw materials, and controlled production processes, the company supports consistent quality across batches of leatherette office and tech accessories. This provides customers with the reassurance that their ordered products will match in color, texture, and functional performance, regardless of the production date.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634