Are Leatherette Name Badges Environmentally Friendly and Safe, and Can They Pass Relevant Tests?

Overview of Leatherette Name Badges and Material Characteristics

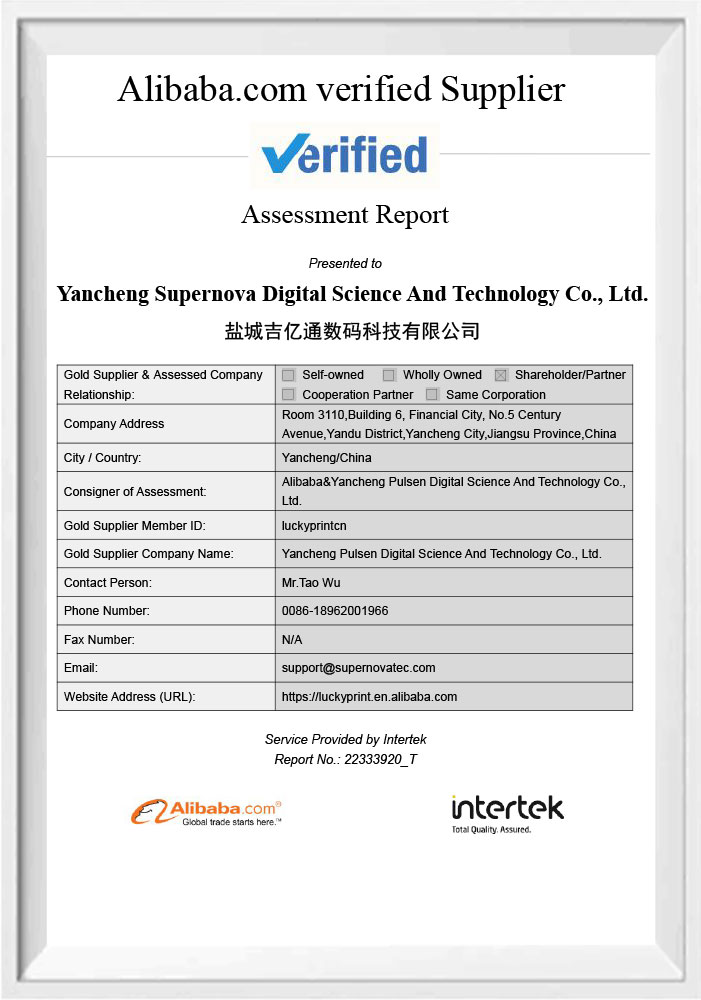

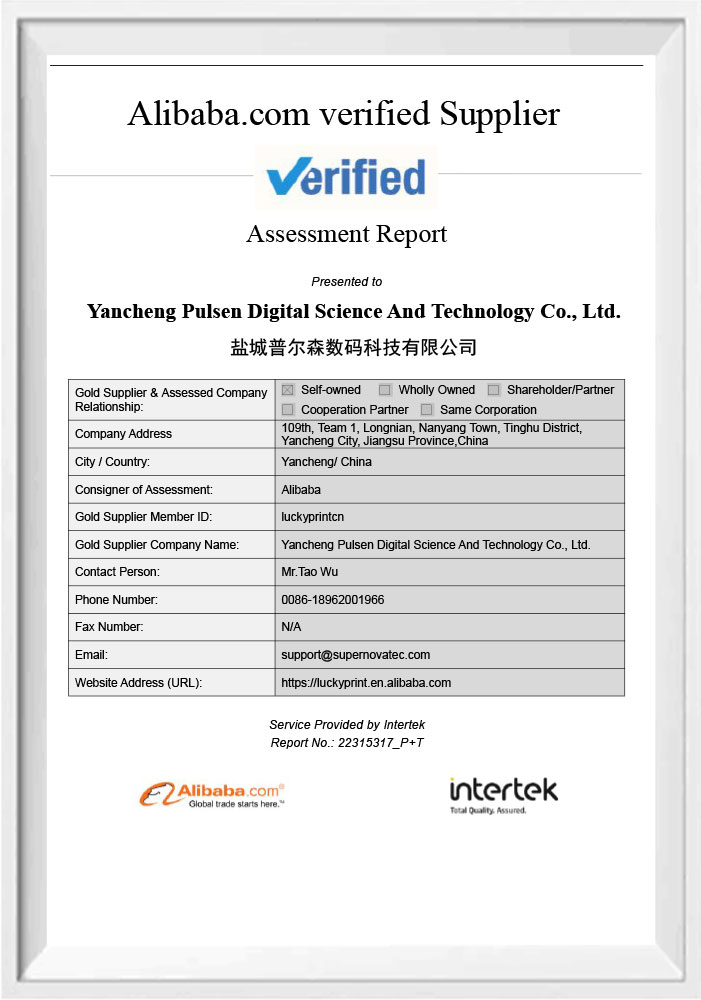

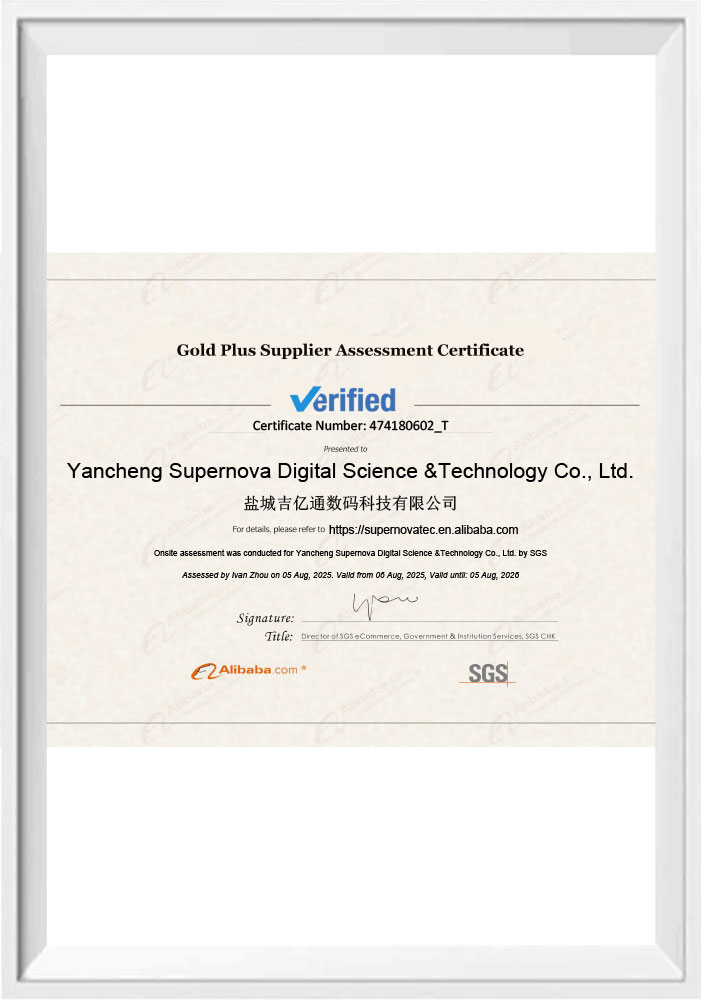

Leatherette name badges are commonly used in corporate events, retail environments, conferences, and service industries due to their refined appearance and consistent texture. These products typically use synthetic materials that imitate the look and feel of leather while remaining cost-effective and easier to process. As the market demand for personalized and customizable accessories continues to grow, leatherette name badges have become a practical option for businesses looking for durable identification solutions. Yancheng Supernova Digital Science & Technology Co., Ltd., established in 2009, is a manufacturer and supplier specializing in sublimation blanks and laser blanks, including leatherette keychains, cigar cases, and various personal accessories. The company’s long-term experience in material research and production provides a reliable foundation for evaluating the environmental and safety aspects of leatherette name badges.

Environmental Considerations of Leatherette Materials

The environmental friendliness of leatherette name badges depends on the composition of the synthetic materials and the production methods used. Many leatherette materials utilize polyurethane-based substrates because they allow for flexibility, smooth printing surfaces, and a leather-like finish without relying on animal-derived components. From an environmental perspective, this can be beneficial for companies aiming to reduce the use of natural leather and support responsible material sourcing. Yancheng Supernova Digital Science & Technology Co., Ltd. focuses on developing sublimation-ready leatherette materials, which means they are designed to efficiently accept dyes using heat transfer processes. This reduces waste during decoration and supports cleaner production cycles compared with more chemical-heavy printing methods. Additionally, the durability of leatherette name badges contributes to environmental value, as products with a long service life require fewer replacements, thereby minimizing resource consumption.

Safety Properties and Human Contact Suitability

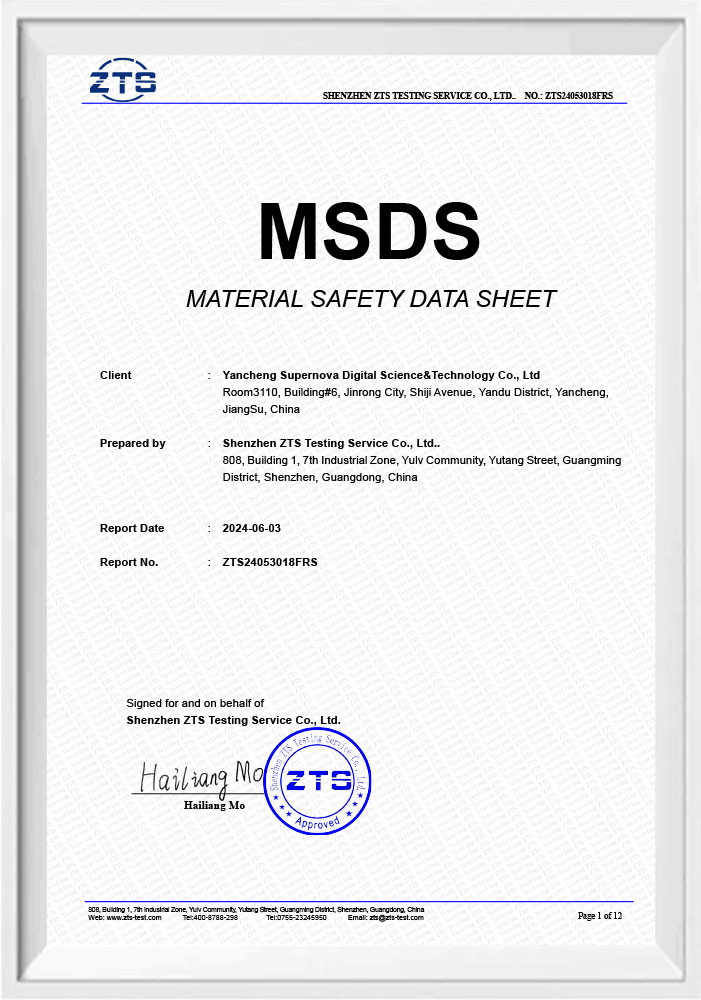

Safety is a key concern for accessories worn directly on clothing or near the skin. Leatherette name badges produced by manufacturers such as Yancheng Supernova Digital Science & Technology Co., Ltd. are designed to maintain stable performance during use and resist issues like color fading, cracking, or releasing unpleasant odors. The safety of these products also relates to their resistance to common environmental factors such as moisture, light exposure, and temperature variation, ensuring that they remain comfortable and non-irritating. As the company specializes in sublimation blanks and laser blanks, its materials are intended for high-temperature processing, which requires stable substrates that do not release harmful substances during heating. This processing requirement indirectly supports overall product safety, as only materials capable of meeting these conditions without degradation can be used.

Compliance and Relevant Testing Standards

Leatherette name badges can undergo several types of tests depending on the target market, including chemical safety tests, abrasion resistance tests, colorfastness tests, and structural durability tests. Yancheng Supernova Digital Science & Technology Co., Ltd., as a provider of sublimation and laser-compatible materials, designs its products to align with industry expectations for safe and stable processing. For example, the materials used for leatherette surfaces generally comply with limits for harmful substances such as lead, cadmium, or certain phthalates, ensuring that they meet common regulatory requirements found in consumer goods standards. Moreover, because sublimation printing requires exposure to high temperatures, materials are typically pre-tested to ensure they maintain physical and chemical stability. This supports downstream compliance with certifications related to workplace ID accessories, promotional goods, and general consumer product safety.

Examples of Typical Tests for Leatherette Name Badges

The following table provides an example of test categories often applied to leatherette accessories to evaluate their environmental and safety performance. While specific results depend on individual formulations, manufacturers like Yancheng Supernova Digital Science & Technology Co., Ltd. develop products with these testing expectations in mind.

| Test Category | Purpose | Expected Criteria |

| Chemical Safety Test | Check for restricted substances such as heavy metals or plasticizers | Within regulatory limits |

| Colorfastness to Rubbing | Evaluate the resistance of printed surfaces to friction | Minimal surface color transfer |

| Temperature Resistance | Ensure material stability during sublimation or laser processing | No deformation or harmful emission |

| Abrasion Resistance | Assess product durability during regular handling or badge use | Surface remains intact after repeated friction |

Practical Application of Leatherette Name Badges in Various Industries

Leatherette name badges are widely adopted in industries that value both presentability and durability. The smooth surface makes them suitable for detailed sublimation printing, company logos, or personalized identification. Yancheng Supernova Digital Science & Technology Co., Ltd. supplies leatherette materials that support fine laser engraving, which further enhances customization options while maintaining clean edges and consistent engraving depth. When businesses choose badges produced from stable leatherette substrates, they gain the advantage of uniform appearance and long-term reliability. The suitability of these badges for different workplace environments, including hospitality, retail, and corporate settings, demonstrates how environmental and safety considerations integrate with real-world usability.

Factors Influencing Test Outcomes and Product Selection

The ability of leatherette name badges to pass required tests depends on the base materials, adhesives, coatings, and processing techniques used during manufacturing. Suppliers such as Yancheng Supernova Digital Science & Technology Co., Ltd. that specialize in sublimation blanks apply careful material selection to ensure that substrates react predictably under heat and pressure. Businesses evaluating leatherette name badges should consider whether the products originate from manufacturers with established experience in synthetic material development. They should also confirm that badges undergo appropriate pre-production testing, particularly when used in environments requiring dependable identification accessories. Understanding the material composition and intended processing conditions helps buyers select products that align with their safety expectations and environmental requirements.

Will Leatherette Name Badges Fade After Long-Term Use?

General Characteristics of Leatherette Name Badges

Leatherette name badges are commonly used in office environments, hospitality settings, retail stores, conferences, and various corporate activities due to their consistent texture, clean appearance, and compatibility with multiple printing methods. These badges typically rely on synthetic materials designed to replicate the look and feel of natural leather while offering stable performance for daily use. Yancheng Supernova Digital Science & Technology Co., Ltd., established in 2009, is a manufacturer specializing in leatherette keychains, cigar cases, and personal accessories. The company also focuses on the research and production of sublimation blanks and laser blanks, which ensures that its leatherette surfaces are engineered to perform reliably during customized printing processes. Understanding the characteristics of leatherette materials is essential for determining how well they maintain their color and surface quality over long-term use.

Factors Affecting Color Stability of Leatherette Surfaces

The potential for fading in leatherette name badges depends on several conditions, including exposure to sunlight, friction during daily wear, cleaning frequency, and printing techniques used. Leatherette materials often incorporate polyurethane-based layers, which provide a stable base for color application and help resist environmental influences. For products manufactured by companies like Yancheng Supernova Digital Science & Technology Co., Ltd., the surface is specifically prepared to accept sublimation or laser engraving, meaning the material must maintain consistent performance under heat. This requirement contributes to better color stability because only substrates capable of handling high-temperature processes without distortion or discoloration are used. Additionally, the protective coatings applied to leatherette surfaces help preserve printed details and reduce the chance of color fading during extended use.

Performance of Sublimation Printing on Leatherette Materials

Sublimation printing is one of the most common decoration methods used for leatherette name badges due to its ability to create detailed, long-lasting images. Yancheng Supernova Digital Science & Technology Co., Ltd. specializes in sublimation blanks, meaning their leatherette products are designed to achieve reliable dye penetration and high-definition imprinting. During sublimation, dyes transform into gas under heat and bond with the upper layers of the leatherette surface. This process embeds color rather than placing it on top of the material, which helps reduce the likelihood of fading over time. Because the color becomes part of the substrate, it is more resistant to environmental factors such as routine contact, variations in indoor lighting, and general workplace conditions. As long as the badge is used within normal temperature ranges and not exposed to harsh cleaning chemicals, sublimation-printed leatherette surfaces generally maintain their color integrity for extended periods.

Laser Engraving Effects on Surface Durability

Laser engraving is another highly compatible method for leatherette name badges, producing crisp text and patterns without relying on ink or dyes. Yancheng Supernova Digital Science & Technology Co., Ltd. produces laser blanks specifically designed to yield consistent engraving depth while maintaining smooth edges. Since the laser removes a thin surface layer to reveal the contrasting underlayer, fading is typically less of a concern compared with printed designs. Engraved markings remain visible even under repeated handling and do not wear away easily because they are physically etched into the material. This makes laser-engraved leatherette badges a stable option for environments where badges are exposed to frequent contact, such as reception desks, retail counters, or hospitality workplaces.

Environmental Conditions That May Influence Long-Term Appearance

Although leatherette materials demonstrate stable performance, certain environmental conditions can influence color retention. Exposure to direct ultraviolet light for extended periods may gradually affect the surface appearance, especially for badges worn outdoors or stored in sunny areas. Similarly, frequent contact with abrasive surfaces or harsh cleaners may gradually reduce surface smoothness, affecting the visual quality of printed areas. To maintain their appearance, users should avoid leaving badges under strong sunlight for long durations and should follow appropriate cleaning practices using mild, non-abrasive materials. Manufacturers like Yancheng Supernova Digital Science & Technology Co., Ltd. develop their leatherette products with these conditions in mind, selecting materials and coatings designed to provide dependable appearance retention during routine use.

Typical Tests Used to Evaluate Fading Resistance

Manufacturers conduct multiple tests to assess the fading resistance of leatherette name badges. These tests help determine how the products respond to simulated long-term use as well as exposure to different environmental factors. The following table provides examples of commonly used assessments:

| Test Type | Purpose | Assessment Focus |

| Colorfastness to Light | Evaluate resistance to sunlight or UV exposure | Degree of color change after controlled light exposure |

| Colorfastness to Rubbing | Measure durability under routine friction | Color transfer or surface wear |

| Sublimation Heat Stability Test | Verify material performance during high-temperature printing | Surface integrity and unchanged color after heating |

| Chemical Resistance Test | Assess sensitivity to cleaners or workplace chemicals | Retention of color and texture |

How Material Quality Influences Long-Term Use

The quality of the base materials used in leatherette name badges has a significant impact on fading resistance. Yancheng Supernova Digital Science & Technology Co., Ltd., with its focus on sublimation and laser-ready materials, applies controlled formulations that enhance surface durability during both production and daily use. Stable polyurethane layers, consistent thickness, and well-applied protective coatings contribute to the badge’s ability to maintain its appearance. This means that businesses choosing badges from reliable manufacturers generally experience fewer issues with premature fading or surface degradation.

Practical Considerations for Maintaining Color Longevity

Users can take several practical steps to preserve the color and clarity of leatherette name badges. Storing badges away from direct sunlight, avoiding exposure to strong chemical cleaners, and minimizing friction against rough clothing or accessories can help maintain their original look. In workplace environments where badges are frequently touched or repositioned, selecting laser-engraved options may provide additional stability. With proper care and by choosing products from experienced manufacturers like Yancheng Supernova Digital Science & Technology Co., Ltd., leatherette name badges can retain their color and visual appeal even during long-term use.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634