What types of synthetic materials are typically used in Leatherette Frames, Certificate Holders, and Ornaments? In what performance aspects do these materials have advantages or disadvantages compared to traditional genuine leather, wood, or metal?

Commonly Used Material Types

Leatherette Frames, Certificate Holders, and Ornaments typically use several main synthetic materials to mimic the look and texture of genuine leather. Common materials include:

- PVC (Polyvinyl Chloride): PVC is a commonly used synthetic leather material with good water resistance and stain resistance. Its surface can be coated to achieve a similar effect to genuine leather. PVC is often used in lower-priced Leatherette products, making it cost-effective.

- PU Leather (Polyurethane Leather): PU leather is an environmentally friendly and moderately cost-effective material, typically used in higher-end Leatherette products. It mimics the texture of leather by pressing a polyurethane coating onto textile fabric. PU leather not only boasts a soft, comfortable feel but is also more environmentally friendly because its production process does not require the use of animal hides.

- Other synthetic leathers (such as TPE, TPU, etc.): These materials perform well in terms of softness, elasticity, durability, and environmental friendliness, making them suitable for high-end or customized Leatherette products.

Comparison with Traditional Materials

Durability:

- Leatherette (PVC, PU leather) offers higher water and stain resistance compared to traditional genuine leather, is easier to clean, and less prone to moisture and mold. However, genuine leather, due to its natural structure, is generally more durable over long-term use, gradually becoming softer and more lustrous with use.

- Compared to wood and metal, Leatherette may be slightly less durable, especially under high friction or prolonged exposure to sunlight. Metal and wood are stronger and more stable, but their surfaces are more susceptible to scratches, corrosion, or moisture damage.

Weight:

- Leatherette is generally lighter than genuine leather, wood, or metal. This makes it more convenient for making picture frames and certificate frames, especially for decorative items that need to be frequently moved or hung; its lightweight nature is ideal.

- In contrast, wood and metal are generally heavier, which may limit their convenience, especially for home or commercial use.

Environmental friendliness:

- PU leather is more environmentally friendly than PVC because its production process does not involve harmful chlorination, and PU leather generally does not contain toxic substances such as heavy metals.

- Genuine leather, while natural, has a significant environmental impact due to the use of animal hides in its production process, especially if not properly dyed, as it can pollute water sources.

- Wood and metal materials are generally environmentally friendly if derived from sustainable resources, but the environmental impact of logging and smelting processes cannot be ignored.

How are Leatherette Frames, Certificate Holders, and Ornaments manufactured? Are molding, injection molding, hot pressing, or other processes used to ensure their shape stability and structural integrity? What are the effects of these processes on product quality and appearance?

Common Manufacturing Processes

The manufacturing processes for Leatherette Frames, Certificate Holders, and Ornaments typically include the following:

- Molding: Molding is commonly used to produce Leatherette Frames, Certificate Holders, and Ornaments with specific shapes and textures. Heated Leatherette material is pressed into a mold, and after cooling, it forms the predetermined shape. Molding helps to create a uniform texture or pattern on the material surface, enhancing the product's decorative effect.

- Injection Molding: While injection molding is more commonly used for producing plastic parts, some modern Leatherette products may also incorporate this technology. The basic frame structure is formed by injecting liquid plastic or synthetic materials, followed by hot pressing or lamination to add the Leatherette surface. This process improves production efficiency and precision, making it suitable for mass production.

- Heat Pressing: Hot pressing is widely used to bond Leatherette material to other substrates (such as wood, metal, or plastic), typically used to produce high-quality picture frames and certificate frames. Through the combination of heat and pressure, the Leatherette surface is firmly fixed to the substrate, retaining its texture and appearance.

- Laser Engraving and UV Printing: These processes are often used for custom patterns and personalized designs, allowing for the engraving of fine text or patterns on the frame surface with high precision, suitable for personalization and small-batch production.

Impact on Product Quality and Appearance

- Molding Process: Molding allows Leatherette frames to showcase exquisite textures and patterns, enhancing their decorative appeal. Simultaneously, it helps ensure surface uniformity and structural stability. For complex shapes or custom designs, molding offers better precision and consistency.

- Injection Molding Process: Injection molding is typically suitable for mass production, ensuring consistent size and shape for each product. While it reduces production time and labor costs, it may not offer the same level of fine detail and texture as molding or hot pressing.

- Hot Pressing Process: Hot pressing provides strong adhesion and surface smoothness, contributing to improved durability and texture. This process typically maintains a beautiful appearance while ensuring structural stability and long-term durability.

- Laser Engraving and UV Printing: These technologies allow for added detail and highly personalized customization options. Laser engraving offers extremely high precision, enabling the creation of intricate patterns and text on the surface of Leatherette without affecting its structure or durability. UV printing provides a rich variety of colors and patterns to suit diverse design needs.

Are Leatherette Frames, Certificate Holders, and Ornaments prone to aging or damage over time? How can surface wear, fading, or cracking be prevented? Are there specific maintenance methods to extend the lifespan of these products?

Aging and Damage of Leatherette Frames, Certificate Holders, and Ornaments

Over time, Leatherette Frames, Certificate Holders, and Ornaments may be affected by environmental factors, leading to aging, wear, fading, or cracking. Especially in environments with high temperature, high humidity, or prolonged direct sunlight, the surface coating of the product is prone to change, affecting its appearance and durability. This situation usually occurs in lower-quality Leatherette products, while high-quality Leatherette materials can reduce these problems to some extent.

Measures to Prevent Surface Wear, Fading, and Cracking

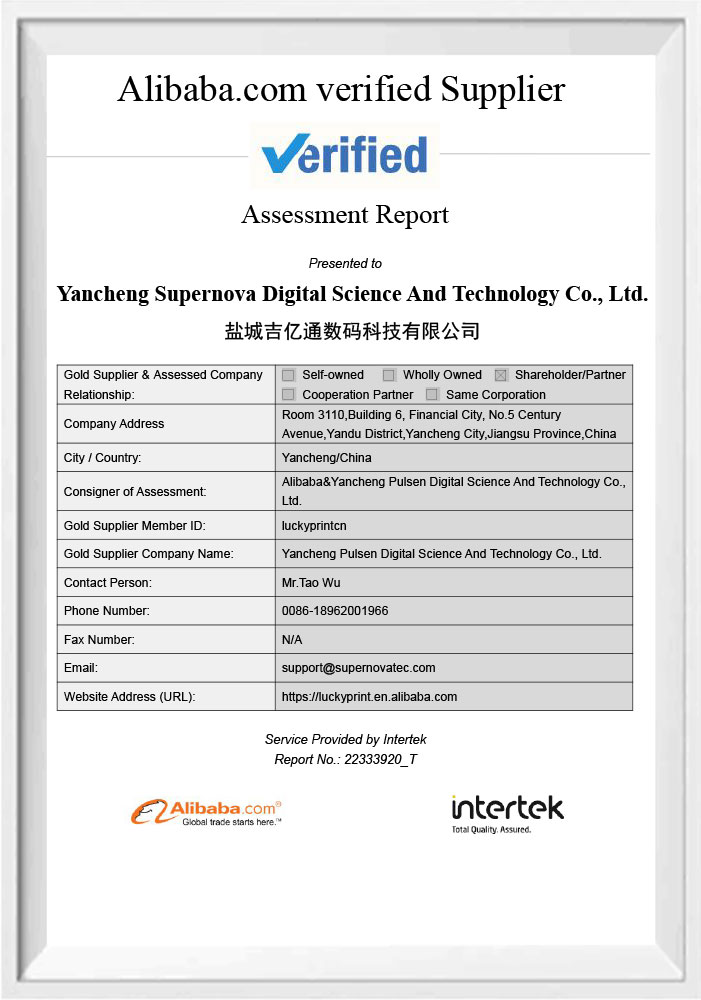

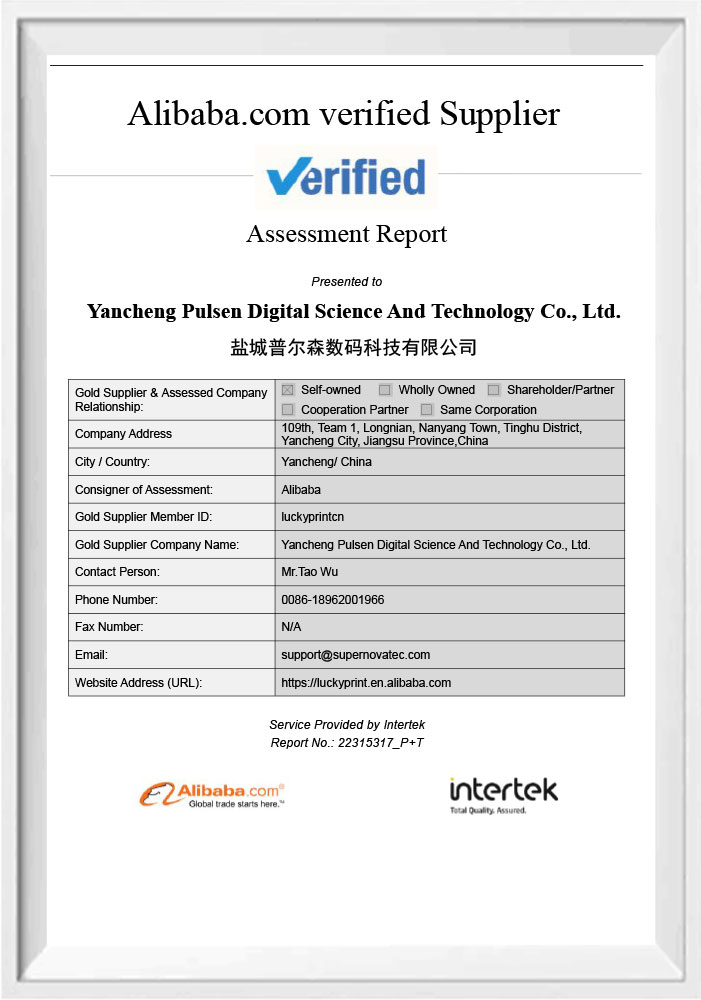

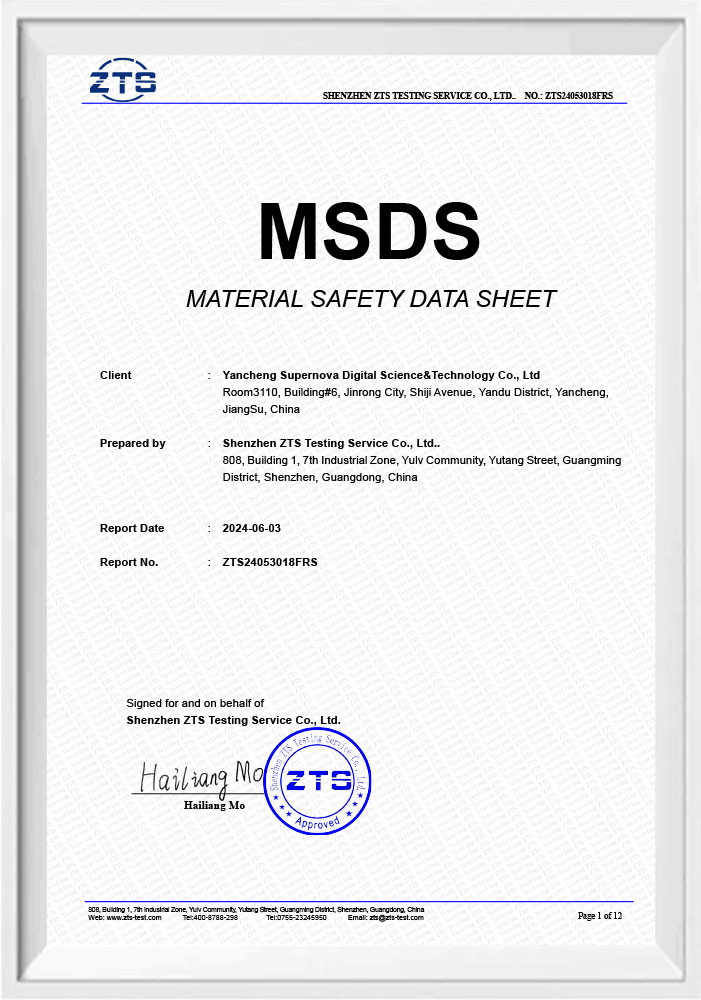

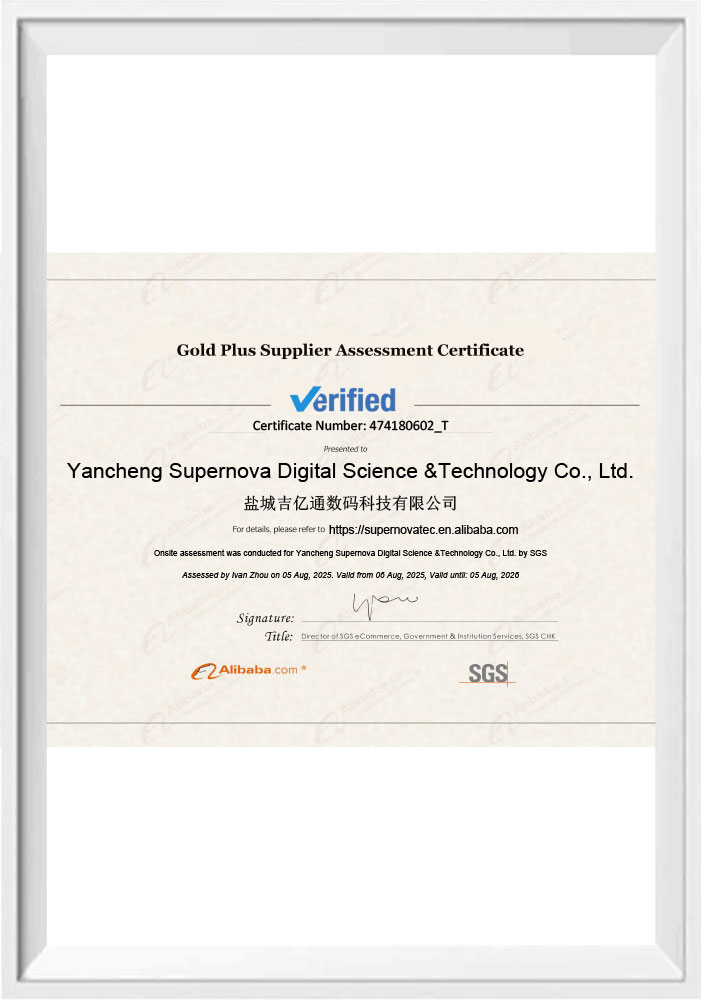

- UV Protective Coating: To effectively resist fading and aging caused by ultraviolet (UV) radiation on the surface of Leatherette Frames, Certificate Holders, and Ornaments, a UV-protective coating significantly extends the product's lifespan. This coating effectively slows down UV erosion, maintaining vibrant colors and improving durability. Just as Yancheng Supernova Digital Science & Technology Co., Ltd. uses high-quality laser-compatible Leatherette substrates in its research and development, ensuring stability during high-intensity laser engraving and daily use.

- Regular Maintenance and Cleaning: Use a soft cloth to regularly wipe the frame surface to prevent the accumulation of dust and stains. For stubborn stains, choose a cleaner suitable for Leatherette materials; avoid using solvent-based products to prevent damage to the surface coating.

- Avoid Extreme Environments: To minimize damage from environmental factors, avoid exposing Leatherette frames to strong sunlight, humidity, or extreme temperatures. Especially during long-term storage, it is recommended to store them in a dry, cool place.

Maintenance Methods to Extend Service Life

- Innovative Technology and High-Quality Materials: Yancheng Supernova Digital Science & Technology Co., Ltd. focuses on providing high-quality laser-engraved Leatherette substrates, ensuring the stability and durability of the material over long-term use. By using proprietary production processes, such as laser engraving and thermal transfer technology, we can guarantee high-quality customized patterns and logos while avoiding the wear or peeling problems that can occur with traditional printing methods. Furthermore, as a company committed to continuous innovation, our Laserable Leatherette products have special abrasion resistance in their surface treatment, providing a longer user experience while maintaining an excellent appearance.

- Surface Protective Coating: During the manufacturing process at Yancheng Supernova Digital Science & Technology Co., Ltd., we employ special surface coatings and treatment processes. This not only helps protect Leatherette products from stains and scratches but also effectively delays color fading and material aging. Through technological safeguards in the production process, our Laserable Leatherette substrates are better suited to withstand the various external pressures of daily use.

- Customer Education and Maintenance Recommendations: We also provide customized maintenance recommendations and product care methods to help customers extend the lifespan of their products. After purchase, we recommend regular inspection and cleaning of the products, using appropriate tools and products to maintain the appearance and function of picture frames and certificate frames. These maintenance methods help prevent damage caused by improper cleaning or unsuitable usage environments.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634