Surface Treatments for Leatherette Coasters

UV Coating: In the production of Leatherette coasters, a UV coating (ultraviolet coating) is often used to enhance their abrasion resistance, stain resistance, and water resistance. A UV coating is a coating formed through ultraviolet light curing technology, which effectively improves the surface's scratch resistance, UV resistance, and high-temperature resistance. After using a UV coating, the surface of the Leatherette coaster is not only easier to clean but also more durable, with significantly improved water resistance, preventing water stains and beverage spills from penetrating the material.

Hot Pressing: Another common surface treatment is hot pressing. By heating the Leatherette material and applying pressure, a fine texture can be formed on its surface, mimicking the natural texture of leather. This treatment is not only aesthetically pleasing but also enhances the feel of the coaster, making it look more upscale.

Polyurethane Coating: Some high-end Leatherette coasters use a polyurethane (PU) coating. A PU coating enhances the material's softness and comfort, and provides additional stain protection. PU coatings are highly durable and prevent the penetration of liquids such as oil, wine, and coffee stains.

Texture Embossing: Besides UV coatings, embossing or texturing is also a common surface treatment process. A mold is used to emboss the surface of the Leatherette coaster, creating a leather-like texture. This process not only enhances the visual appeal but also improves the coaster's grip, making it more slip-resistant.

Heat Transfer and Screen Printing: For customized designs, Leatherette coasters often use heat transfer or screen printing techniques. Heat transfer allows for the printing of intricate patterns or brand logos onto the coaster surface, resulting in vibrant colors that are resistant to fading. Screen printing is suitable for mass production and simple graphic designs, and is relatively inexpensive.

Customization Processes and Costs of Leatherette Coasters

Color and Pattern Customization: Leatherette coasters offer great flexibility in customization. For colors, common Leatherette coasters are available in a variety of shades, including classic black, brown, white, and gray, as well as more vibrant colors. For special colors, color matching techniques are typically used.

Pattern and Logo Customization: For pattern customization, Leatherette coasters can use processes such as heat transfer printing, screen printing, and laser engraving to print brand logos, advertisements, and patterns. Heat transfer printing is suitable for complex patterns and multi-color designs, producing clear and durable images; laser engraving is suitable for simple text and graphics, leaving a deep and lasting mark on the coaster surface.

Customization Process: The customization process typically involves the following steps:

- Design Confirmation: The client provides the pattern, color, and size requirements, and the designer will create a layout and confirm it.

- Sample Production: Based on the design, a sample is made for confirmation, ensuring that the quality and effect meet expectations. 3. Production: After sample confirmation, mass production begins. Production time and complexity vary depending on the process (e.g., heat transfer, screen printing, or laser engraving).

Customization Costs: The cost of custom Leatherette coasters is influenced by several factors:

- Quantity: Small-batch customization typically has a higher unit price, while large-batch production can reduce costs through wholesale pricing.

- Customization Process: Complex patterns or multi-color heat transfer printing are more expensive than standard monochrome screen printing. Laser engraving is priced according to the complexity of the pattern.

- Materials and Size: Higher quality Leatherette material or extra-large coasters will increase production costs.

Custom coasters are typically suitable for corporate promotions, gift companies, the catering industry, and other applications requiring personalized design.

Leatherette Coaster Cleaning and Maintenance Requirements

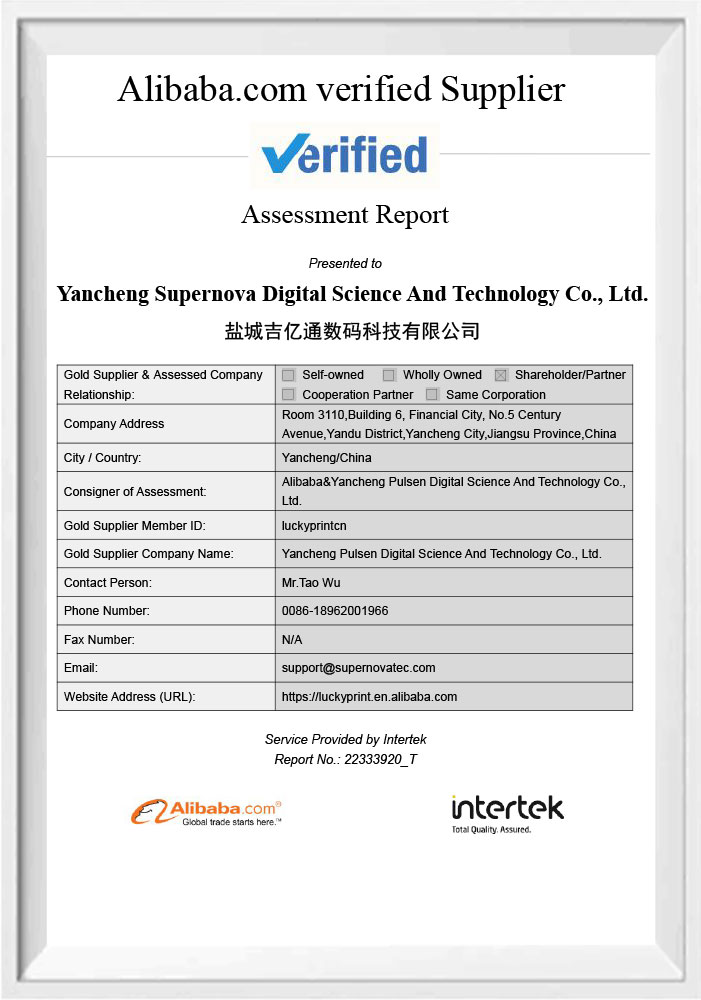

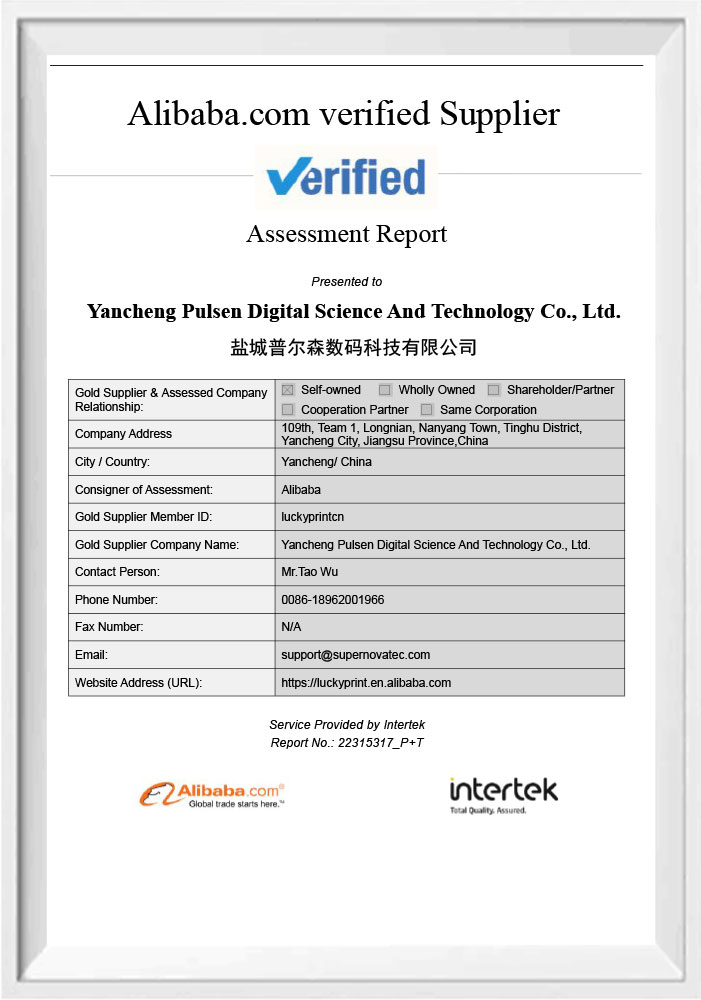

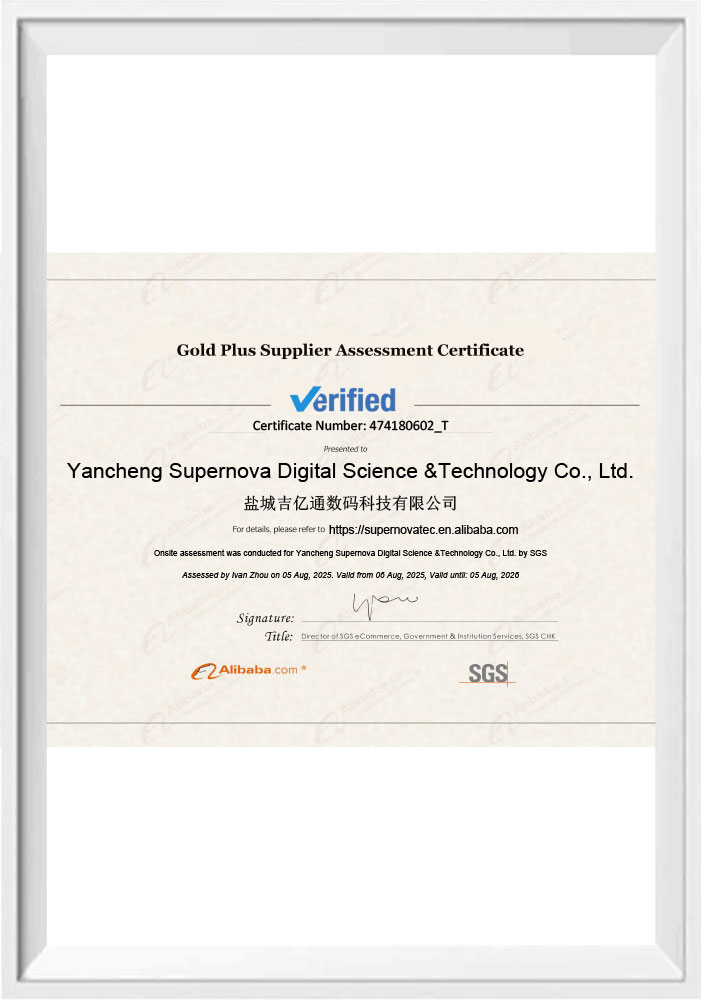

Ease of Cleaning: Leatherette coasters are known for their smooth, durable surface and ease of cleaning. Since Yancheng Supernova Digital Science & Technology Co., Ltd. began trading sublimation blank products in 2009 and has been manufacturing them in its own facilities since 2012, the company's product quality and standardized production have been recognized by the industry. Our company uses advanced manufacturing processes to ensure that the surface of each Leatherette coaster has excellent water and stain resistance, so common stains such as water stains, oil stains, and tea stains on the coasters can be easily removed in daily use.

Simple cleaning methods include wiping with a damp cloth, and using mild soapy water if necessary. Through the company's continuous innovation in sublimation and laser engraving technologies, laser-engravable Leatherette blank material was developed in 2016, ensuring that these coasters are not only aesthetically pleasing but also have excellent durability and cleaning performance.

Maintenance Requirements: While Leatherette coasters are durable, prolonged exposure to extreme temperatures may cause material aging or surface fading. To maintain their optimal condition, regular cleaning is recommended, and they should be kept away from excessively hot or humid environments. Given our company's commitment to innovation and technological advancement, **in 2024 we further expanded our product line to include laser-engraved acrylic sheets**, maintaining the same focus on durability and ease of maintenance for each product. Therefore, Leatherette coasters can also be maintained and cleaned regularly using appropriate preservatives to extend their lifespan.

Stain Resistance and Home Applicability: Thanks to the continuous technological innovation of Yancheng Supernova Digital Science & Technology Co., Ltd. since its inception, including the development of laser engraving technology to enhance the durability of Leatherette products, the stain resistance of Leatherette coasters has been greatly improved. These coasters effectively resist contamination from everyday beverages such as coffee and tea, and are quite easy to clean without the need for special cleaning agents.

As a company with its own manufacturing facility, our laser-engravable Leatherette material features high-quality surface treatment and detailed polishing, ensuring that the coasters maintain their new appearance even with frequent daily use. For home users, Leatherette coasters are not only beautiful and practical, but also very easy to maintain, keeping them in good condition for a long time.

English

English  Español

Español  Deutsch

Deutsch

86-15851089634

86-15851089634