Introduction of Leatherette Pet Collars Briefly introduce leatherette pet collars and their growing popularity. Leatherette pet collars have emerged as a dominant force in the pet ...

Read MoreLaserable Leatherette: The Ultimate Guide for Crafters and Businesses

2025-11-11Introduction to Laserable Leatherette

What Is Laserable Leatherette?

Laserable leatherette refers to a type of leatherette material engineered to respond well to laser processing, including laser engraving leatherette and laser cutting leatherette. It is typically made from synthetic fibers coated with a smooth, leather-like surface that offers the appearance of real leather while remaining more consistent in texture. This consistency makes engraving faux leather more predictable compared with natural hides. When subjected to the appropriate laser settings for leatherette, the surface reacts by producing sharp, clear markings without excessive melting or discoloration. Because faux leather engraving does not rely on natural grain patterns, the results tend to be more uniform. Laserable leatherette is widely used in craft production, commercial branding, and custom decor because it balances durability, appearance, and ease of customization. It has gained attention in the maker community, especially for users who want professional-looking results with accessible materials.

Benefits of Using Laserable Leatherette

One benefit of laserable leatherette is its adaptability. Since the leatherette material is synthetic, it maintains a consistent thickness that supports both engraving and cutting techniques. This predictability allows users to experiment with different laser settings for leatherette without encountering major variations across batches. Another benefit is that faux leather engraving with a laser produces clean details suitable for fine text, decorative borders, and intricate patterns. Many small manufacturers and hobbyists appreciate how laser engraving leatherette contributes to the production of custom leatherette gifts, branded products, and promotional items. Furthermore, laserable leatherette is generally more affordable than genuine leather, which helps reduce waste in experimental or small-scale production. Because the material is available in a wide range of colors and textures, it supports creative flexibility. It is often used for items that need a polished appearance but do not require the natural aging or patina associated with real leather.

Applications of Laserable Leatherette

Laserable leatherette is applied in numerous industries because it works well with both laser engraving and laser cutting leatherette methods. Companies use it for branded office items, awards, plaques, and packaging elements. In the personalization market, custom leatherette gifts such as wallets, notebook covers, coasters, and keychains are commonly produced using faux leather engraving. The material also performs well in signage and display applications, where engraved text must remain readable and visually consistent. Many makers incorporate laserable leatherette into craft projects that require flexibility and durability, including embroidered patches, bag labels, and decorative accessories. The controlled reaction of the leatherette material to laser energy allows for precision in repeat production, which is important when creating multiple identical pieces. For commercial and hobbyist environments, laserable leatherette is a practical choice due to its compatibility with common CO₂ laser systems and its ability to offer detailed engraving results.

Common Uses and Key Characteristics of Laserable Leatherette

| Application | Processing Method | Key Characteristics |

|---|---|---|

| Custom leatherette gifts | Laser engraving leatherette | Clean details, consistent results |

| Office accessories and branding | Engraving faux leather | Professional appearance, customizable |

| Craft and hobby projects | Laser cutting leatherette | Flexible material, suitable for shapes |

| Labels and patches | Engraving and cutting | Durable surface, precise outlines |

| Decorative signage | Laser engraving | High contrast, readable text |

Material Behavior During Laser Processing

When using laserable leatherette, the reaction of the material to laser energy is an important factor to consider. Proper laser settings for leatherette help operators achieve clear engraving results without burning through the upper layer. This top layer is designed to separate cleanly under controlled heat, revealing a contrasting color beneath. This layered design supports detailed faux leather engraving suitable for graphics and text. During laser cutting leatherette, the material melts slightly at the edges to form a sealed border, which helps reduce fraying. These characteristics make the material desirable for projects requiring defined shapes or repetitive cutting. The synthetic base layer remains stable under standard CO₂ laser frequencies, ensuring that the engraved pattern is visible and durable. Understanding how the leatherette material reacts to varying power levels and speeds helps avoid damage and maintain consistent quality in both small-scale and large-scale production.

Why Designers and Makers Choose Laserable Leatherette

Designers often choose laserable leatherette because it supports creativity without requiring specialized equipment beyond a standard laser engraver. Makers appreciate how laser engraving leatherette enables detailed personalization across multiple product categories. Since engraving faux leather avoids many of the inconsistencies associated with natural leather, it becomes easier to produce items that match in color and texture. The ability to create custom leatherette gifts appeals to both commercial clients and individual consumers. Additionally, the flexibility of the material encourages experimentation with new patterns, layered designs, and mixed-material products. The surface finish of laserable leatherette tends to handle contrast well, allowing engraved areas to stand out clearly. Its compatibility with common fabrication processes, including stitching, bonding, and assembly, further supports its versatility. As a result, laserable leatherette continues to gain popularity among professionals who value predictable results and efficient workflows.

Introduction to Laserable Leatherette

Faux Leather vs. Real Leather

Laserable leatherette is a synthetic leatherette material specifically engineered to respond effectively during laser engraving leatherette and laser cutting leatherette processes. Unlike real leather, which varies in grain, thickness, and surface structure, faux leather used for engraving faux leather maintains consistency, making it well suited for precision work. Real leather can require different laser settings for leatherette-like processing because natural hides respond unpredictably to heat and may produce uneven marks. Faux leather engraving, by contrast, produces clearer lines and more uniform results. For users creating custom leatherette gifts, faux leather offers predictable color reactions and controlled depth of engraving. Although real leather has a natural aesthetic, its irregularities can complicate engraving, while laserable leatherette provides a reliable surface for both detailed artwork and repeated production. This difference is one reason many makers prefer laserable leatherette when consistency and efficiency matter.

Different Colors and Textures

Laserable leatherette is available in an extensive variety of colors and textures, allowing for creative flexibility in both design and production. The leatherette material is manufactured with consistent pigmentation and surface finish, which supports stable engraving results across multiple pieces. This reliability is important for those producing custom leatherette gifts that must match brand colors or design themes. In faux leather engraving, the top layer of the leatherette material reacts to the laser by revealing a contrasting secondary color, so selecting the right color combination significantly affects the final appearance. Some textures mimic natural grain, while others offer smooth or patterned surfaces suited for projects involving laser cutting leatherette. These variations support branding, decorative work, and product differentiation. Because the material responds predictably under well-adjusted laser settings for leatherette, users can explore different colors and textures without worrying about inconsistent reactions.

Thickness and Durability

The thickness of laserable leatherette influences how the material behaves during both laser engraving and laser cutting. Thicker leatherette material provides more body and can be used for items such as notebook covers, coasters, or structured accessories. Thinner material, on the other hand, is flexible and well suited for projects involving sewing or layering. When applying laser settings for leatherette, operators often adjust speed and power based on thickness to avoid burning or incomplete cuts. Even though the material is synthetic, it maintains durability that supports long-term use in custom leatherette gifts and functional accessories. Faux leather engraving results tend to stay legible and maintain contrast over time because the engraved layer does not fade easily. For users producing patches, labels, or decorative components, choosing the correct thickness ensures that the material remains both workable and structurally sound, whether stitched, glued, or assembled with hardware.

Common Types of Laserable Leatherette

| Type | Characteristics | Best Use |

|---|---|---|

| Smooth leatherette | Even surface suitable for detailed faux leather engraving | Logos, fine text, custom leatherette gifts |

| Textured leatherette | Grain patterns that resemble natural leather | Decorative pieces, patches, labels |

| Two-tone leatherette | Contrasting color revealed during laser engraving leatherette | High-contrast designs, signage |

| Thick leatherette | Durable material with structural support | Coasters, covers, rigid accessories |

| Thin leatherette | Flexible material compatible with sewing and layering | Wearable items, soft labels |

Material Behavior Under Laser Processing

The engineered surface of laserable leatherette allows for predictable reactions during engraving faux leather. The upper coating is designed to separate cleanly when exposed to laser heat, producing clear marks without excessive residue. When using laser cutting leatherette, the edges may seal slightly due to melting, which reduces fraying and supports precise shaping. Adjusting laser settings for leatherette—such as power, speed, and focus—is important because it helps avoid over-penetration or burning. The synthetic structure of the leatherette material ensures consistent performance across different colors and textures, making it easier to produce multiples of the same design. This reliability is especially valuable for commercial production or bulk orders of custom leatherette gifts. Because the material maintains stability under common CO₂ laser wavelengths, it is compatible with many types of laser equipment used by hobbyists, designers, and manufacturers.

Why Color, Texture, and Thickness Matter in Project Planning

Selecting the right type of laserable leatherette depends on the intended application and the desired final appearance. Smooth surfaces work well for intricate artwork or branding, where clarity and precision are essential. Textured surfaces provide depth, which can enhance large engraved patterns created during faux leather engraving. Thicker leatherette material supports structural items, while thinner options are ideal for flexible pieces or projects requiring stitching. Laser settings for leatherette may need slight adjustments depending on the chosen type to ensure clean engraving and accurate cuts. These considerations help makers plan projects more efficiently and avoid material waste. Whether producing laser engraving leatherette designs, crafting labels, or manufacturing custom leatherette gifts, understanding the characteristics of each leatherette type contributes to better results and smoother workflow. Designers and hobbyists benefit from experimenting with different materials to discover combinations that best suit their aesthetic and functional goals.

Laser Engraving on Leatherette: A Step-by-Step Guide

Preparing Your Design

Preparing a design for laser engraving leatherette involves understanding how the leatherette material reacts to the beam and how visual elements transform during engraving. Since laserable leatherette is engineered to respond consistently to controlled heat, the design phase should consider contrast, line clarity, and engraving depth. Whether the goal is to produce custom leatherette gifts or experiment with faux leather engraving for branding purposes, clean vector artwork tends to deliver predictable results. Designers often refine line weights, simplify shapes, and adjust contrast so that each engraved area maintains clear definition after processing.

Working with high-resolution artwork is important because low-quality images may lead to rough edges when engraving faux leather. Many creators rely on software such as Illustrator, CorelDRAW, or other vector-based tools to prepare files that the laser machine can interpret accurately. The choice of fonts, spacing, and layout also influences how laser cutting leatherette or engraving patterns appear after finishing. Since leatherette has a synthetic surface layer, delicate patterns usually engrave more consistently when they are not excessively thin. Preparing multiple versions of a design can help determine which option will interact most effectively with the laser settings for leatherette during test runs.

Design preparation also includes determining the final purpose of the engraved item. For example, custom leatherette gifts such as keychains, notebooks, or wallets require different visual proportions compared with decorative panels. Engraving areas should be sized appropriately to avoid distortions caused by stretching or bending the leatherette material during use. By testing small segments first, creators can confirm whether the design’s density produces the desired engraved tone, especially when applying laser engraving leatherette techniques that differentiate between light and dark fill areas.

| Design Element | Recommended Approach | Common Considerations |

|---|---|---|

| Line Thickness | Use moderate-weight strokes | Avoid overly thin lines that may fade |

| Image Resolution | High-resolution vector preferred | Prevents pixelation during engraving |

| Contrast Balance | Ensure clear tonal separation | Affects engraving visibility on leatherette |

Choosing the Right Laser Settings

Selecting laser settings for leatherette is a central part of achieving consistent results because the surface structure and synthetic layers react differently depending on heat and speed. For most laserable leatherette, moderate power and high speed are used to avoid cutting fully through the material unless laser cutting leatherette is the goal. Faux leather engraving typically requires lower power than real leather because leatherette material tends to mark quickly without deep penetration. As each brand of leatherette varies slightly, initial test strips help identify the balance between power and speed that produces clean edges and avoids overheating.

Those working with engraving faux leather frequently adjust settings based on color and texture variations. Darker leatherette may show lighter engraved marks, while lighter leatherette can reveal slightly darker impressions, depending on the coating. Air assist can sometimes be reduced to prevent residue spread, though this depends on the machine’s capabilities. Since laser engraving leatherette focuses on surface marking rather than deep engraving, lower-frequency pulses often produce smoother results. Adjusting DPI also affects the way fine details appear, as higher DPI can deliver more detailed marks but may slow down processing time.

Maintenance of consistent settings across batches is important when producing multiple custom leatherette gifts. Calibration of the laser lens, cleanliness of the machine, and consistent material placement assist in maintaining uniformity. Because the leatherette material may differ in thickness among manufacturers, rechecking the focus height helps keep engraving lines sharp. Choosing the right settings is an iterative process that improves the quality of faux leather engraving as experience accumulates.

| Setting Type | Typical Range | Purpose |

|---|---|---|

| Power | Low to moderate | Prevents excessive burn or cut-through |

| Speed | Moderate to high | Maintains clean surface marks |

| DPI | 250–400 | Balances detail with processing time |

Step-by-Step Engraving Process

The engraving process begins by preparing a test sample to verify the interaction between the chosen design and the leatherette material. After securing the leatherette flat on the laser bed, ensuring it does not curl or shift, the operator imports the design into the machine’s software. The alignment tools available in most laser software help position the pattern precisely where engraving faux leather will appear on the final product. Adjusting focus height is important because even slight deviations can soften engraved details.

Once alignment is confirmed, the selected laser settings for leatherette are applied. The first pass is generally used solely for surface marking, ensuring that the engraving does not cut deeper than intended. Many operators observe the engraving process closely during the initial seconds to identify whether adjustments are needed. Leatherable leatherette reacts quickly to heat, so minor refinements such as reducing power or increasing speed can be made before running subsequent batches. For laser cutting leatherette applications, a separate cutting pass may be added with adjusted power and slower speed.

After the engraving pass finishes, checking the engraved area helps confirm whether the depth and contrast match expectations. When producing custom leatherette gifts that include multiple engraved sections—such as a notebook cover with a name and logo—operators often run small alignment tests first. This step-by-step verification prevents misalignment and ensures that the engraving remains visually balanced across the leatherette material.

| Process Step | Main Task | Key Outcome |

|---|---|---|

| Setup | Position and secure leatherette | Prevents movement during engraving |

| Focus Adjustment | Set precise beam distance | Improves engraving clarity |

| Engraving Pass | Run selected laser settings | Marks design onto the surface |

Cleaning and Finishing

After completing the engraving process, cleaning the surface helps enhance the clarity of laser engraving leatherette. Mild cleaning agents or a dry cloth can remove residue produced during engraving. Since leatherette material often includes a protective surface layer, gentle wiping is usually sufficient. Abrasive cleaning tools should be avoided because they may dull the engraved areas. For faux leather engraving that produces fine powdery residue, a low-strength rubbing alcohol solution can help clear remaining particles without affecting the synthetic surface.

Finishing work also includes checking for loose edges or inconsistencies. When laser cutting leatherette has been used to shape items such as keychains or labels, edges may be lightly sealed by the laser, but some sections might require trimming. Custom leatherette gifts often receive additional finishing steps such as stitching, adhesive bonding, or hardware installation. Ensuring that engraved areas remain clean and undamaged helps maintain the intended appearance of the final product.

Storage and handling further influence how the engraved leatherette material holds its engraved details over time. Avoiding prolonged exposure to direct heat, moisture, or excessive friction helps preserve the engraved finish. When properly cleaned and protected, faux leather engraving can maintain its visual stability, making it suitable for long-term decorative or functional applications.

Laser Engraving Ideas and Inspiration

Personalized Gifts

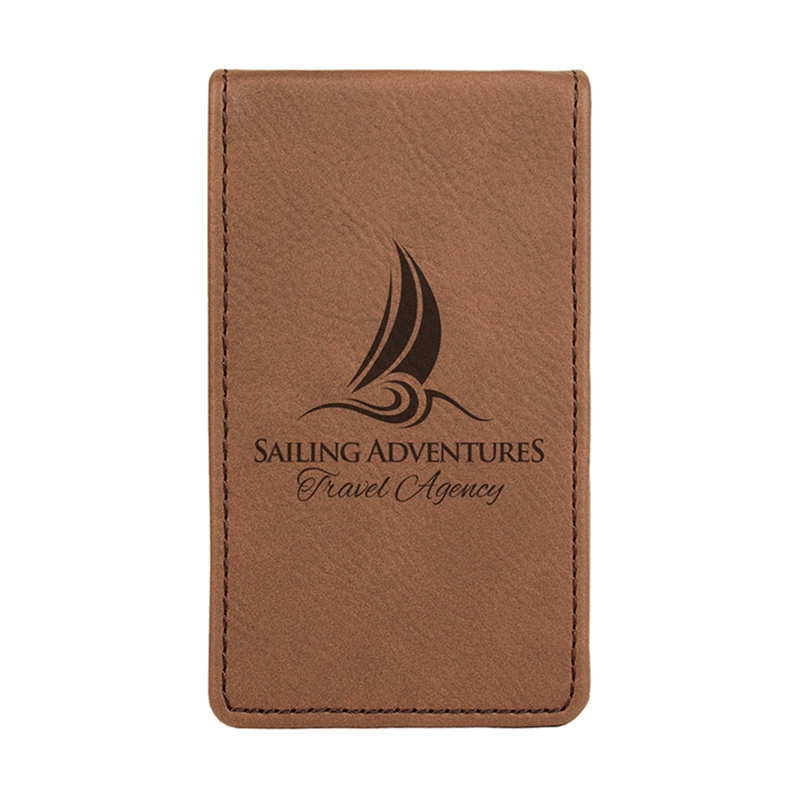

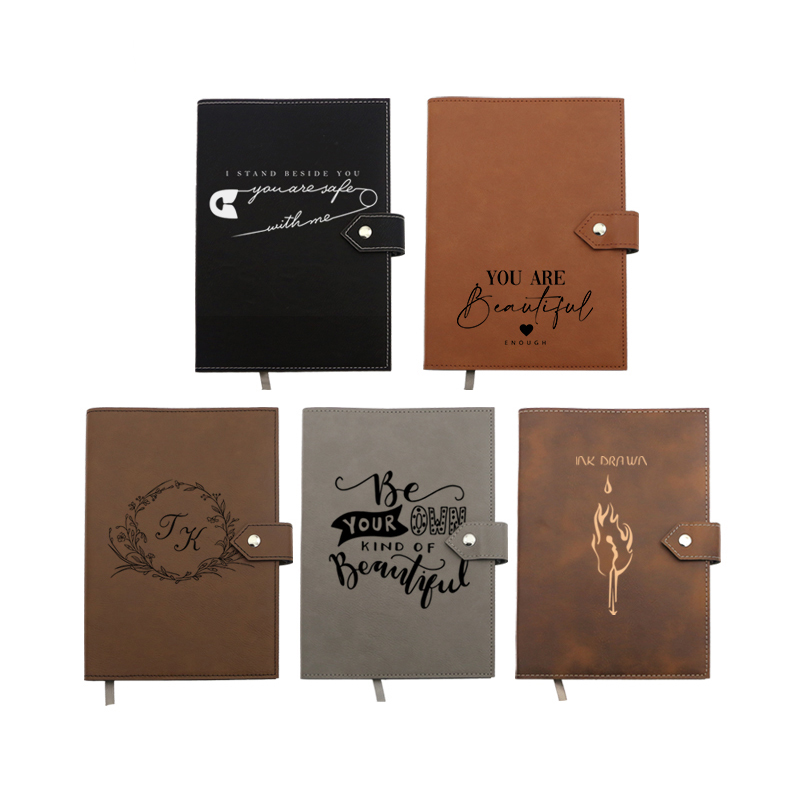

Creating personalized gifts with laserable leatherette offers a wide range of artistic and functional possibilities. The consistent response of leatherette material to controlled heat makes it suitable for detailed patterns, names, dates, and logos. Many creators use laser engraving leatherette to produce custom leatherette gifts such as keychains, bookmarks, flask wraps, photo frames, and journal covers. These items deliver a tactile appearance that resembles real leather while allowing more repeatable results, especially when engraving faux leather that maintains uniformity across large batches.

One advantage of faux leather engraving for personalized gifts is the design flexibility. The smooth synthetic coating reacts predictably to laser energy, creating contrasts that highlight engraved text or decorative patterns. Since the laser settings for leatherette can be adjusted to achieve light or dark marking effects, makers can tailor each design to match the gift’s theme. Whether engraving monograms for wedding gifts or custom logos for business promotions, the engraved surface tends to maintain its appearance without requiring extensive finishing work.

The process also benefits from the ability to combine engraving with laser cutting leatherette. By cutting precise shapes, creators can produce decorative tags, luggage labels, coasters, and specialty ornaments. The combination of cutting and engraving on leatherette material allows artisans to develop layered designs that pair visual appeal with functionality. Personalized gifts remain one of the most popular applications because they allow individuals to express identity, celebrate occasions, or create brand-specific merchandise through engraving faux leather.

| Gift Type | Engraving Feature | Leatherette Advantage |

|---|---|---|

| Keychains | Names, initials, small icons | Durable surface marking |

| Journals | Logos, quotes, patterns | Large engraving area |

| Coasters | Geometric or floral designs | Clean cut edges |

Home Decor

Laser engraving leatherette is widely used in home decor projects because the material provides a refined appearance while remaining easy to shape. Common items such as wall art panels, storage baskets, labels, and decorative signage benefit from engraving faux leather due to its stable engraving behavior. Designers often choose leatherette material because it can mimic natural leather textures without variations that sometimes occur when engraving real leather. This consistency supports detailed patterns, borders, and lettering, allowing decor pieces to carry a cohesive style throughout a living space.

The versatility of laserable leatherette also enables the creation of multi-layered decorative pieces. Artisans frequently use laser cutting leatherette to cut shapes such as botanical motifs, geometric outlines, or word signs that can be combined with engraved backings. When layering multiple colors or textures of leatherette, the final composition gains depth without requiring heavy construction. Home decor items such as desk organizers, drawer tags, and hanging plaques become practical yet decorative solutions that draw on the benefits of engraving faux leather.

Because the laser settings for leatherette can be tuned for subtle shading effects, creators can reproduce illustrations, line art, and silhouette designs that complement various interior themes. Household items like personalized placemats, utensil holders, and decorative trays can incorporate family names or themed artwork through laser engraving leatherette. The material’s stability under moderate laser power also means that large surfaces can be engraved consistently, making it feasible to produce sets of matching decor pieces.

| Home Decor Item | Design Application | Function |

|---|---|---|

| Wall Panels | Patterns, quotes, logos | Decorative focal piece |

| Storage Baskets | Engraved labels | Organizational clarity |

| Placemats | Border designs or monograms | Dining presentation |

Fashion Accessories

Faux leather engraving has become increasingly popular in the design of fashion accessories because leatherette material offers stability and consistency for detailed engraving. Items such as wallets, handbags, belts, wristbands, luggage tags, and cardholders can all be enhanced with laser engraving leatherette techniques that add personalization or decorative elements. The synthetic surface of leatherette responds well to fine lines, making it possible to engrave patterns that enhance the accessory’s appearance without compromising its structure.

Many creators explore fashion accessories with a combination of laser cutting leatherette and engraving. For example, cutting intricate patterns allows designers to incorporate perforated details into straps or decorative panels. Engraving faux leather can be used to add branding, artistic motifs, or messaging that aligns with the accessory’s style. The ability to engrave consistently across multiple items helps maintain uniform branding for small businesses creating custom leatherette gifts in the fashion sector.

Another advantage is the wide variety of available textures and colors. Laserable leatherette comes in smooth, grainy, metallic, and multi-tone finishes, enabling designers to experiment with contrasting effects. Subtle engraving patterns on dark leatherette create an understated look, while deeper engraving on lighter materials offers more visible contrast. Adjusting the laser settings for leatherette allows precise control over these effects, helping designers create accessory collections with coordinated themes. Many fashion makers also appreciate the durable nature of engraved surfaces, which continue to display detail even as the item undergoes regular use.

| Accessory Type | Engraving Application | Design Focus |

|---|---|---|

| Wallets | Logos, initials, geometric patterns | Identity and decoration |

| Handbag Panels | Floral or abstract engravings | Artistic texture |

| Luggage Tags | Names, icons, travel motifs | Recognition and personalization |

Troubleshooting Common Issues for Laserable Leatherette

Burning

Burning is one of the most frequently encountered issues when working with laserable leatherette, especially for beginners who are still learning how to fine-tune their laser settings for leatherette. Because leatherette material is a synthetic composite designed to react predictably under laser energy, excess heat can still lead to unwanted burn marks. These marks often occur when the laser power is set too high or the engraving speed is set too low, causing concentrated heat to remain on the surface for too long. Burning may also happen when attempting highly detailed faux leather engraving, as closely spaced lines can increase heat accumulation.

To reduce the risk of burning during laser engraving leatherette, users can make incremental adjustments to both power and speed until a balanced setting is achieved. Lowering the laser power and increasing the speed helps distribute heat more efficiently. Air assist also plays an important role by directing airflow across the engraving area, which helps cool the surface and remove residue. When creating custom leatherette gifts that require deeper engraving, it may be more effective to perform multiple light passes rather than a single heavy pass. This method helps prevent overheating while maintaining clean engraving results.

Another way to mitigate burning is through material preparation. Wiping the leatherette material with a soft cloth before engraving removes dust and surface particles that could char when heated. When using laser cutting leatherette, a small shift in focus height may also help reduce burning along the cut edges. Monitoring the material closely during test runs can help ensure that burn marks are avoided, maintaining the visual consistency needed for engraving faux leather while ensuring that each engraved gift meets quality expectations.

| Cause of Burning | Possible Adjustment | Outcome |

|---|---|---|

| High laser power | Reduce power settings | Less surface charring |

| Slow engraving speed | Increase engraving speed | Lower heat accumulation |

| Residue on surface | Clean material before engraving | Cleaner, more consistent marks |

Inconsistent Engraving

Inconsistent engraving can occur with laserable leatherette when the laser does not apply uniform energy across the entire surface. This may result in some areas appearing lighter, while others show deeper or darker markings. Variations in faux leather engraving often stem from issues such as uneven focus, inconsistent airflow, worn laser lenses, or changes in the leatherette material’s backing or texture. Because different brands of leatherette material may vary in thickness or surface finish, inconsistent results can also emerge when switching between suppliers or batches.

One of the most reliable ways to correct inconsistent engraving on leatherette is to start by checking the laser focus. Laser engraving leatherette requires precise focusing to ensure the beam interacts with the surface accurately. If the engraving head is too close or too far from the material, the beam may create irregular lines. Cleaning the lens and mirrors helps maintain consistent beam strength, which is necessary for detailed engraving faux leather projects such as custom leatherette gifts that require uniform lettering or pattern depth.

Adjusting the laser settings for leatherette may also improve consistency. If the engraver applies too much energy in one area or not enough in another, lowering the power slightly and increasing the number of passes can help create more uniform results. Ensuring even airflow by repositioning the air assist nozzle contributes to stable engraving behavior. In some cases, inconsistent engraving may occur because the leatherette material is not positioned flat on the work surface. Securing the sheet with tape or magnets prevents shifting, which helps maintain consistent line alignment during the engraving or laser cutting leatherette process.

| Inconsistency Cause | Corrective Action | Expected Result |

|---|---|---|

| Poor focus | Refocus the laser | Even engraving depth |

| Dirty lens or mirrors | Clean optical components | Stable beam output |

| Uneven surface placement | Flatten and secure material | Smoother engraving lines |

Material Warping

Material warping sometimes occurs when laserable leatherette is subjected to prolonged heat exposure or when the heat generated during engraving causes the synthetic layers to contract or expand unevenly. Warping can be especially noticeable when engraving large areas of leatherette material with high coverage designs. The internal structure of the material reacts to temperature shifts, which may lead to curling edges or slight bends. When producing custom leatherette gifts such as placemats, notebook covers, or signage pieces, warping can affect both the appearance and ease of assembly.

To minimize warping during laser engraving leatherette, users can reduce the heat load by lowering laser power and increasing movement speed. This adjustment ensures that the laser does not dwell on one area for too long. Employing multiple lighter passes instead of a single heavy pass distributes heat more evenly. Additionally, using air assist helps maintain cooler temperatures as engraving progresses, reducing the likelihood of surface distortion. Engraving faux leather with high-density patterns may require evaluating whether the design needs adjustments to balance areas of heavy and light coverage.

Warping may also be influenced by environmental conditions. Leatherette material stored in high humidity or low humidity environments can react differently once exposed to laser energy. Allowing the material to acclimate to the workshop environment before engraving can improve stability. When performing laser cutting leatherette, securing the edges during the cutting process helps maintain flatness. After engraving, placing the leatherette material under a flat weight for a few hours can help reduce any minor warping resulting from heat exposure.

| Warping Cause | Suggested Adjustment | Benefit |

|---|---|---|

| Heat buildup | Increase speed, reduce power | Lower temperature impact |

| High-coverage designs | Use lighter passes | More uniform heat distribution |

| Environmental humidity | Acclimate material before use | Better engraving stability |

Tips for Success with Laserable Leatherette

Proper Storage

Proper storage is one of the key steps in achieving consistent results when working with laserable leatherette. Because leatherette material is made from synthetic fibers and a supportive backing, temperature and humidity changes can influence its flexibility and surface texture. Storing the material in a climate-controlled environment helps prevent curling, warping, or dryness that may affect how it reacts during laser engraving leatherette projects. When leatherette is exposed to excessive heat, the material may soften or expand, while cold conditions may cause stiffness that makes it harder to secure flat on the engraving bed.

To prepare faux leather engraving materials for production, many users prefer to keep sheets stored flat rather than rolled. This helps maintain even tension across the surface, which is especially important when creating custom leatherette gifts that require precise alignment. If rolling is required for transportation or storage, loosely rolling the leatherette material around a wide tube can help prevent creases. Keeping the material away from direct sunlight also protects the top layer from fading or drying. Before beginning a project involving laser cutting leatherette or engraving faux leather, it is helpful to allow the material to rest in the workshop environment for several hours so it can adapt to local temperature and humidity conditions.

| Storage Issue | Recommended Solution | Effect on Engraving |

|---|---|---|

| Material curling | Store flat and weighted | Improves surface stability |

| Heat exposure | Use climate-controlled space | Protects texture and backing |

| Low humidity stiffness | Allow acclimation time | Better engraving consistency |

Testing and Experimentation

Testing and experimentation are essential for working effectively with laserable leatherette, especially since the material can vary based on color, texture, backing, and brand. Even small differences between batches may influence how the surface reacts to particular laser settings for leatherette. Conducting test engravings on scrap pieces helps users determine the optimal balance between power, speed, and resolution. This approach avoids the risk of over-engraving or under-engraving, both of which can affect the final appearance of engraving faux leather patterns.

Laser engraving leatherette often requires adjusting settings depending on the intended design. For intricate patterns, lighter power with slower speeds tends to produce cleaner lines without excessive heat buildup. For deeper or more contrasted markings, users may choose to run multiple passes instead of one intense pass. These methods help maintain the integrity of the leatherette material while achieving the desired engraved effect. When testing laser cutting leatherette, experimenting with different focus settings can also influence edge quality and minimize the risk of rough or melted borders.

Experimentation extends to the choice of design as well. Some custom leatherette gifts, such as keychains, coasters, or portfolio covers, may look better with bold vector outlines, while others may benefit from raster engraving for shading effects. By conducting small-scale trials, users can identify the visual style that best complements the material. Documenting all successful settings and practice results creates a reference that supports future engraving faux leather projects, helping to maintain consistency and reduce production errors.

| Testing Factor | What to Adjust | Expected Benefit |

|---|---|---|

| Engraving depth | Power and speed | Achieves desired contrast |

| Edge quality | Focus height adjustments | Smoother laser-cut edges |

| Design style | Vector vs. raster selection | Better visual results |

Safety Precautions

Safety precautions are important when using laser equipment with leatherette material. Although laserable leatherette is designed for engraving, it still contains synthetic components that may give off light fumes or adhesive odors during processing. Ensuring proper ventilation in the workspace helps maintain clean air quality and supports long-term equipment reliability. Many laser systems include exhaust fans or filtration units that help remove airborne particles generated during laser engraving leatherette or laser cutting leatherette. Keeping these systems in good condition ensures safe operation and prevents buildup inside the machine.

Users should also wear appropriate safety gear when working with laser equipment. Laser-safe glasses may be necessary depending on the type of machine. Additionally, it is essential to avoid leaving the engraver unattended during operation. Leatherette material, like many synthetics, can react unpredictably if incorrect settings are used, which may lead to overheating or surface damage. Monitoring each engraving session helps reduce risk and ensures the quality of engraving faux leather projects.

Another important safety step is proper machine maintenance. Dust, residue, and microscopic material particles can accumulate on engraver lenses or mirrors, affecting beam accuracy and increasing the risk of irregular engraving. By regularly cleaning these components, users support smoother engraving performance and extend equipment longevity. These precautions not only protect the operator but also help maintain consistent quality when producing custom leatherette gifts or large production batches of leatherette material.

| Safety Concern | Preventive Measure | Result |

|---|---|---|

| Fume exposure | Use proper ventilation | Cleaner workspace air |

| Machine overheating | Monitor equipment during use | Reduced project risks |

| Optics contamination | Regular cleaning schedule | Improved engraving accuracy |

Contact Us

Your email address will not be published. Required field are marked*

-

-

Why Choose Laser Engraved Leather Patches for High-Quality Custom Designs? When it comes to custom designs for fashion, branding, and accessories, the materials you choose play a c...

Read More -

Introduction to Laserable Leatherette What Is Laserable Leatherette? Laserable leatherette refers to a type of leatherette material engineered to respond well to laser processing, ...

Read More -

Unveiling the World of Leatherette Coasters: Beyond Basic Tableware Defining the Coaster: An Essential Home Accessory Before delving into the unique advantages of Leatherette Coast...

Read More

English

English  Español

Español  Deutsch

Deutsch