Introduction of Leatherette Pet Collars Briefly introduce leatherette pet collars and their growing popularity. Leatherette pet collars have emerged as a dominant force in the pet ...

Read MoreElevate Your Hat Patches with Laserable Acrylic Sheets

2026-01-13

When it comes to crafting standout hat patches, laserable acrylic sheets are revolutionizing the game. These versatile materials combine precision, durability, and eye-catching aesthetics, making them ideal for custom designs that demand attention.

Here’s why acrylic sheets are a must-have for laser engraving and cutting projects:

Why Acrylic Sheets?

- Laser Precision: Acrylic sheets respond flawlessly to laser technology, allowing intricate details and sharp edges. Whether you’re engraving logos, patterns, or text, the results are crisp and professional .

- Durability: Unlike traditional materials, acrylic is resistant to wear, water, and fading. Your hat patches will maintain their vibrant look even after repeated washing and exposure to the elements .

- Versatile Design: Available in a spectrum of colors, finishes (glossy, matte, mirror), and thicknesses (3mm to 10mm+), acrylic lets you experiment with textures and effects. For example, mirror acrylic adds a luxe touch, while colored sheets create bold statements .

- Easy Application: Many acrylic sheets come with heat-activated adhesive backing, simplifying attachment to hats. Use a dual-heated hat press at 320°F (bottom) and 280°F (top) for secure bonding without damage .

Perfect for Hat Patches

Acrylic sheets shine in hat patch applications:

- Complex Designs: Laser engraving reveals the core color beneath the surface layer, creating striking contrasts. For instance, gold or stainless acrylic laser blacks for a sleek, modern look .

- Lightweight Comfort: Acrylic is featherlight, ensuring patches won’t weigh down hats while offering long-lasting resilience.

- Customization: From sports team logos to fashion labels, acrylic adapts to any style. Pair with laserable leatherette for a premium, layered effect .

Pro Tips for Success

- Material Selection: Opt for cast acrylicfor frosted, high-detail engravings. Extruded acrylic is budget-friendly but best for simpler cuts .

- Laser Settings: Use a CO2 laser (10W+) for optimal results. Adjust power and speed based on thickness—thicker sheets (e.g., 8mm) require higher wattage .

- Cleaning: Remove laser residue with non-toxic degreasers like LA Awesome, ensuring your patches stay pristine.

Conclusion

Laserable acrylic sheets are the ultimate canvas for hat patch innovation. Their precision, durability, and design flexibility make them a top choice for brands and creators alike. Ready to take your headwear to the next level? Explore our range of acrylic sheets and start crafting patches that turn heads.

Shop now and discover why acrylic is the future of laser-engraved fashion!

Contact Us

Your email address will not be published. Required field are marked*

-

-

Why Choose Laser Engraved Leather Patches for High-Quality Custom Designs? When it comes to custom designs for fashion, branding, and accessories, the materials you choose play a c...

Read More -

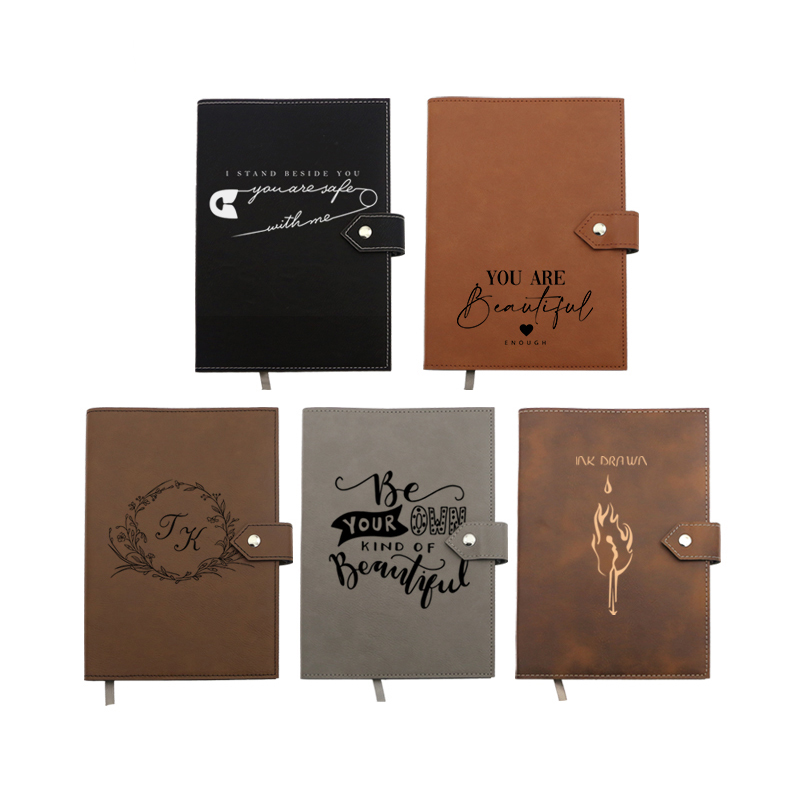

Introduction to Laserable Leatherette What Is Laserable Leatherette? Laserable leatherette refers to a type of leatherette material engineered to respond well to laser processing, ...

Read More -

Unveiling the World of Leatherette Coasters: Beyond Basic Tableware Defining the Coaster: An Essential Home Accessory Before delving into the unique advantages of Leatherette Coast...

Read More

English

English  Español

Español  Deutsch

Deutsch